Ask For A Quick Quote

We will contact you within 1 working day, please pay attention to the email with the suffix “@allenboxes.com”.

Combine your purchasing plan, select the right packaging, including the design, finishing as well as inner tray, and accessories, and use the right shipping.

Because the custom packaging will have a lot of customization costs. For example, we usually create a mold for a new box based on the customer’s product which will bring a mold cost.

It needs to source the material and print mold according to the customer’s design, logo, and color, which will incur printing costs. Some customers prefer to add some attractive finishing, like adding hot stamping, embossing, or Spot UV on the logo which will also generate extra costs.

Some customers need a very high-grade luxury box, such as adding texture to the outside of the box or using special art paper. Some products are packed inside a box with a tray. Some boxes are urgent to participate in exhibitions. Then there will be some additional costs for faster air shipping.

According to the customer’s products and budget, select the correct box which the customer needs. Then design the size of the box, material, color, printing, logo, inner tray, and finishing together.

The cheapest box is not necessarily the best nor is it necessarily what the customer wants. It must be to choose the most suitable for the customer’s packaging and then figure out how to reduce costs together.

For example, the mailer box is shipped in a flat, which can save much shipping costs, and the box cost is also more economical. But many customers prefer high-grade handmade folding boxes. Although the price is higher, but more luxurious, with the customer’s product more with.

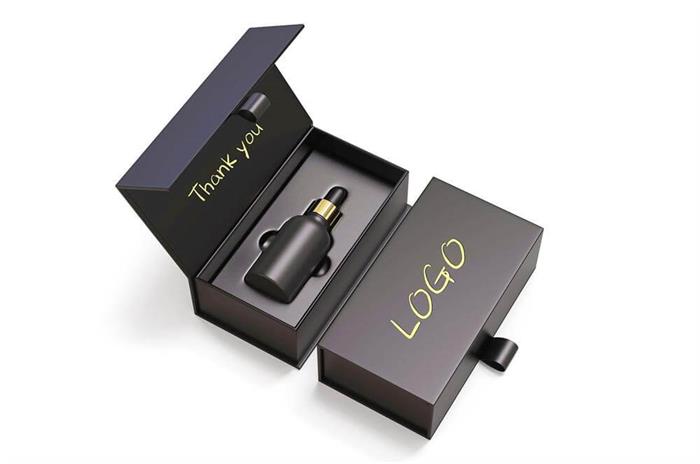

There are also some customers like magnet book-shaped boxes, lid & base boxes, and some other rigid boxes, that can not be folded when shipping, shipping costs will be higher. But it can better protect the customer’s products and is more suitable for displaying the customer’s company culture through some slogans.

2.Reasonable arrangements for samples and mass production.

Although samples can better confirm the quality and are consistent with what the customer wants, also avoids a lot of risks. But sampling takes time and money. If the customer needs it urgently, it could confirm the details with photos and videos. The same for mass production. It’s appreciated if to send samples for clients to approve and sign samples to confirm. After the inspection passed, we will arrange the next production process. After all the steps are completed, we will arrange the final inspection and arrange payment after passed. This is a good way to avoid many risks and customers can be more assured. But it will also be more expensive and time-consuming. If customers need this, they can confirm each step through pictures and videos which saves much time and money.

3.Find a better shipping solution.

Combine the cost of shipping, the time it takes, and when you want to receive those packages. It’s better to find the right shipping options. Some clients prefer the cheapest shipping method, because the packaging product is really not high value, and many times the shipping cost is higher than the cost of the box itself. There are also some customers who have deadlines and must have these packages arrive on the day. So they have to choose faster air freight and of course, it will cost more money.

More customers prefer a door-to-door service that also includes customs tax. The total costs are less and more convenient for the clients. We will find three or more shipping options for our clients to choose from. We just help to arrange the transportation without profit.

We usually suggest that customers who need packing very urgently ship part by air or express, and part by sea transport and train transport, to achieve faster receipt of part of the packing, and also to reduce the total shipping cost.

4.Other suggestions and services.

Before placing an order, it’s appreciated to have a specific purchase plan, including the total quantity you need in one year, when you need it, and what budget you have. Then following this schedule, combined with the regular production time, arrange the samples & mass production, as well as arrange to ship.

If these packages are used in the Christmas promotion in December, you need to receive the packages 3 weeks in advance to pack the products and distribute them to the stores or take some photos to upload them to the website for the promotion. So the packaging must be received before November 15.

Then it is better to start samples in August, arrange production in September, ship in October, and receive in November. The normal sampling dates are 2 weeks to receive the sample, 4 weeks for mass production, about 4 weeks to the United States. Of course, the earlier you start, the better. Because the cost of sea transport varies according to the time of reaching fast and slow, the charges are different.

Multiple products shipped together. We are glad to offer a 1-month free storage service, as well as paid full inspection and packing service. You can ship your clothes, candles, cups, and other products purchased from China to our factory, and we can carefully inspect and pack these products inside the boxes we produced. Then we can arrange shipping together to save shipping costs.

If you don’t have enough warehouse space, but want to purchase more packages at once to reduce unit costs, we are happy to offer a storage service, which is free of charge for 1 month.

There will be very many similar difficulties, and we will find ways to do better.

Contact us and let our professional team assist you, thank you.

Hi, I’m Allen li, the owner of Allenboxes.com, I’ve been in the packaging industry for over 12 years and running a factory in China that produce for 8 years now, and the purpose of this article is to share with you the knowledge related to boxes from a Chinese supplier’s perspective.

We will contact you within 1 working day, please pay attention to the email with the suffix “@allenboxes.com”.