Finishing for custom packaging

Discover the right finishing for custom packaging. APP’s guide covers foil, embossing, spot UV & glitter finishes with cost-benefit analysis for custom paper bags, boxes, cards, etc. Request a finish sample and more info by emails now!

Surface Finishing

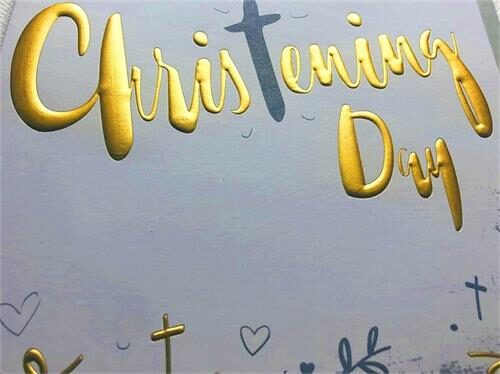

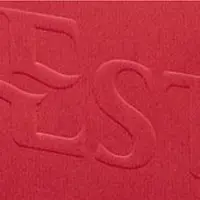

Special Finishing on bag or box or on Logo

How to choose these finishing for custom packaging?

Benefits & Advantages:

- Hot foil/Emboss/Deboss: Elevates brand perception with tactile, high-end finishes (e.g., metallic foil for luxury, embossed logos for memorability).

- Spot UV/Texture: Creates visual contrast and depth (e.g., glossy UV accents on matte surfaces) or sensory appeal (linen textures for eco-conscious brands).

- Glitter: Boosts shelf impact with sparkle (ideal for festive/beauty packaging) while maintaining durability via laminated coatings.

Considerations & Risks:

- Cost/complexity: Foil and multi-step textures raise production costs; simplify designs for budget efficiency (e.g., avoid tiny foil details).

- Material limits: Embossing/debossing requires thicker paper; glitter adhesives may crack on flexible surfaces.

- Consistency risks: Poorly calibrated Spot UV or foil alignment can cause uneven finishes—always test prototypes.