Custom Packaging Style

Discover the right custom packaging style for your brands. APP’s guide analyzes fragility, brand image & costs to optimize custom paper boxes, bags, and eco-mailers. Download our 5-step checklist or ask us more info about customized packaging style by emails!

Popular Packaging styles

6 Core bespoke packaging style

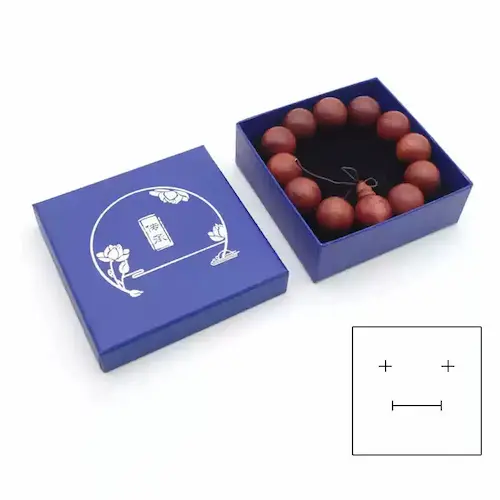

- Custom Luxury Rigid Boxes

Premium structured boxes for high-end retail & lasting brand impressions. - Premium Drawer Boxes

Sleek pull-out design for jewelry, tech & luxury gifting experiences. - Custom Magnetic Closure Boxes

High-end boxes with secure magnets for cosmetics, watches & boutique products. - Wholesale Folding Cartons

Cost-effective, print-ready boxes for retail, food & promotional packaging. - Eco-Friendly Mailer Boxes

Recycled shipping-ready boxes with tamper-proof seams for e-commerce brands. - Customized Luxury Paper Bags

Retail-grade handles & finishes for boutiques, gifts & premium shopping.

- Analyze product size, weight, and fragility to prioritize protection (e.g., boxes for fragile items, bags for lightweight goods).

- Match packaging style to brand image (luxury: lid/base/magnetic boxes; eco-friendly: paper bags/mailers).

- Optimize costs by balancing material, shipping fees, and production complexity (e.g., folding/mailer boxes for budget efficiency).

- Ensure logistics compliance (dimensional weight, stackability) and sustainability goals (recyclable materials).

- Test prototypes for functionality, durability, and customer appeal before bulk ordering.

3 Steps to create Your own custom Packaging style

1. Confirm all details in the description above.

2. Adjust the custom packaging style based on your demand and meet your budget.

- Save the costs by smaller size, thinner materials, simple printing, less special finishing, more quantity, etc.

3. Sampling and trial order to test

- Get samples to approve and have a trial order to test the market if you likethe samples.

More Info & Videos

FAQ about Customizing Packaging

Customization Dimensions

-

Q: Beyond basics, what advanced elements can be customized in printed packaging boxes?

A: Internal lighting systems, scented coatings, RFID tags, magnetic levitation inserts, and thermochromic inks. -

Q: Can corrugated boxes have premium finishes like rigid boxes?

A: Yes! Digital foil stamping (ΔE<2.0), tactile varnish, and micro-embossing now achieve 85% of luxury effects at 40% cost.

Cost Engineering

-

Q: What hidden costs impact custom rigid box pricing?

A: Tooling storage fees: 15−45/month-

Pantone licensing: $150/color/year

-

Compliance testing: 350−1,200/design

-

-

Q: How to reduce setup fees for cosmetic box packaging?

A: Shared production runs – combine with non-competing brands to split $1,200+ die costs.

Structural Innovation

-

Q: Novel box styles beyond standard types?

A: Pyramid boxes (perfume sets)-

Origami-fold boxes (zero glue)

-

Magnetic floating lid boxes (Hettich Tandem hardware)

-

-

Q: Optimal material thickness for personalized candle boxes?

A: 32 ECT B-flute with PE vapor barrier – prevents scent loss (≤0.5g/month) while surviving 200kg stacks.

Printing Technology

-

Q: Digital vs offset printing for packaging printed boxes?

A:Parameter Digital Offset MOQ 100 units 1,500+ units Color Accuracy ΔE 3.0-4.5 ΔE 1.0-1.8 Cost per 1K $185 $85 Lead Time 3-5 days 14-21 days -

Q: Can beauty product boxes have metallic effects sans foil?

A: Metallic digital inks achieve 90% foil look at 0.07/unitvs0.22 for hot stamping.

Sustainability & Compliance

-

Q: Essential eco-certifications for rigid boxes manufacturers?

A: FSC Mix Credit, ISO 14001, OK Compost INDUSTRIAL, and ECF pulp bleaching reports. -

Q: Does customization impact recyclability?

A: Critical thresholds:-

UV coatings ≤12gsm

-

Foil coverage ≤5% surface area

-

Adhesives must pass ASTM D6868

-

Premium Applications

-

Q: Luxury finishes for cosmetic box packaging under 0.50/unit?∗∗ A:∗∗Soft−touchaqueouscoating∗∗(0.08), spot gloss UV (0.12),∗∗blindemboss∗∗(0.18), edge staining** ($0.10).

-

Q: How to integrate Hettich Tandem hinges into rigid gift boxes?

A: Requires 2.5mm+ board with laser-cut slots (±0.15mm tolerance) – adds $0.85/unit but enables 500+ openings.

Protection Engineering

-

Q: Best insert for fragile beauty products?

A: Vacuum-formed PETG trays with memory foam lining – reduces breakage to ≤0.3% vs 5.8% for pulp inserts. -

Q: Drop-test standards for printed corrugated boxes?

A: ISTA 3A: 6 drops from 0.9m | ASTM D5276: 1.2m edge drops – demand test reports.

Cost-Saving Tactics

-

Q: How to cut custom box costs 25% without quality loss?

A: Gang-run printing (4 designs/sheet)-

Standard flute profiles (B or E)

-

Stock white liners (no dye costs)

-

Flat-pack designs (saves 65% freight)

-

-

Q: MOQ workarounds for wholesale custom boxes?

A: Blank stock + pressure-sensitive labels (saves $350+ tooling) | Group buys with complementary brands.

Technical Constraints

-

Q: Minimum legible text size on corrugated boxes?

A: 4pt for offset | 6pt for flexo – below this, use vector graphics or QR codes. -

Q: Why do deep emboss designs crack on recycled board?

A: Recycled fibers have 38% lower tensile strength – limit emboss depth to ≤0.3mm vs 0.8mm on virgin board.

Future Trends

-

Q: Emerging tech in packaging for beauty products?

A: AR trigger patches-

Temperature-sensitive inks

-

Plant-based RFID tags

-

Self-healing coatings

-

-

Q: Blockchain integration for custom printed boxes?

A: QR-linked digital twins track:-

Material origin (FSC CoC)

-

Carbon footprint

-

Authentication history

Adds $0.07/unit but boosts resale value 15%.

-