Finishing for packaging

Discover the right finishing for packaging. APP’s guide covers foil, embossing, spot UV & glitter finishes with cost-benefit analysis for custom paper bags and boxes, cards, etc. Request a finish sample and more info by emails now!

Surface Finishing

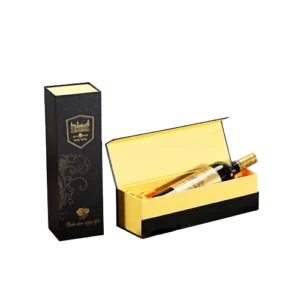

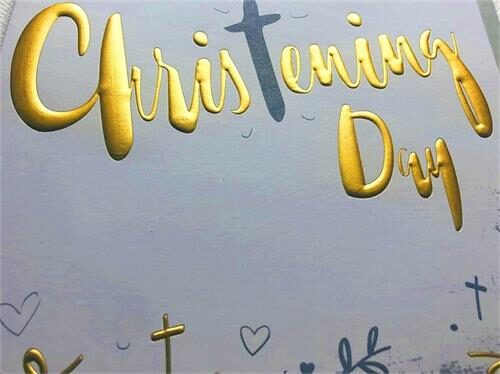

Special Finishing on bag and box or on Logo

How to choose these finishing for custom packaging?

Benefits & Advantages:

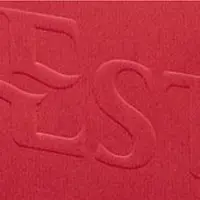

- Hot foil/Emboss/Deboss: Elevates brand perception with tactile, high-end finishes (e.g., metallic foil for luxury, embossed logos for memorability).

- Spot UV/Texture: Creates visual contrast and depth (e.g., glossy UV accents on matte surfaces) or sensory appeal (linen textures for eco-conscious brands).

- Glitter: Boosts shelf impact with sparkle (ideal for festive/beauty packaging) while maintaining durability via laminated coatings.

Considerations & Risks:

- Cost/complexity: Foil and multi-step textures raise production costs; simplify designs for budget efficiency (e.g., avoid tiny foil details).

- Material limits: Embossing/debossing requires thicker paper; glitter adhesives may crack on flexible surfaces.

- Consistency risks: Poorly calibrated Spot UV or foil alignment can cause uneven finishes—always test prototypes.

Investment Spotlight:

Upfront tooling: 100−500 (custom dies)

Material cost: 0.05−0.20/unit (gold foil rolls)

Sweet spot: 500+ units

Brand Magic:

Creates luxury gold logos that scream premium

Perfect for hot stamping brand emblems on gift boxes

Pro Tip:

“Use bold designs – thin lines increase foil waste by 30%”

Cost Breakdown:

80−300 tooling fee

Just 0.10−0.50/unit at 1,000+ volume

Tactile Advantage:

Deboss logos create shadow-play elegance

Blind embossing (no ink) = timeless sophistication

Material Must:

“250g+ paper stock & under 0.5mm depth prevents tears”

3. Combo Punch: Foil + Emboss

Premium Price:

0.30−1.00/unit (dual tooling + precision alignment)

Showstopper Effect:

Hot stamping over emboss = 3D metallic magic

Luxury cosmetics’ secret weapon

Production Hack:

“Foil first → emboss second to avoid adhesive cracks”

4. UV Spotlight Glow

Budget Hero:

0.05−0.20/unit (screen setup + UV resin)

Signature Moves:

Makes UV logos pop against matte backgrounds

Creates scratch-resistant glossy patterns

Crispness Code:“1200+ DPI resolution & ≤60% coverage = eco-friendly shine”

UV & Metallic Finish Optimization

Q: Does UV coating over gold foil affect shine?

A: Yes – reduces reflectivity 25-40%. For luxury boxes, use tactile matte UV or avoid coating over foil.Q: Will UV logos crack in freezer shipping?

A: Standard UV fails below -5°C. Require flexible UV formulations (-30°C Tg) with ISTA 3E certification.Q: Hot stamping vs gold printing costs?

A: Stamping: 320die+0.18/unit. Printing: $0.03/unit but 60% less metallic shine.Q: Why mirror gold foil costs 3x more?

A: Requires pure aluminum, polished chromium dies ($650+), and 30% slower production.

Debossing Engineering

Q: Max deboss depth for magnetic closure boxes?

A: 0.4mm on 2.5mm chipboard – deeper compromises magnetic alignment (±0.3mm tolerance).Q: Can debossed areas hold foil + UV?

A: Only in strict sequence: ① Foil stamp → ② Deboss → ③ Spot UV. Reverse order causes 80% failure.

Compliance & Safety

Q: Is UV coating food-safe?

A: Only with FDA 21 CFR 175.30 compliance – standard UV contains migratable photoinitiators.Q: Does gold foil cause jewelry allergies?

A: Risk if nickel >0.05μg/cm² (REACH). Demand nickel-free certification.

Advanced Applications

Q: Laser debossing for low MOQ?

A: CO₂ laser etching: MOQ 50 units at 0.35/unit(vs1.20+ die). Max 0.2mm depth limitation.Q: Digital vs traditional foil color consistency?

A: Digital foil ΔE variance 2.8-3.5 vs hot stamping’s 0.8-1.2. Hot stamping maintains 100% metallic shine.