Packing Method of Custom Packaging

Discover the right packing method of customized packaging for handmade boxes with APP’s custom packaging guide. Ensure luxury paper bags & high-end boxes arrive safely and cost-effectively. See our 5-step success checklist!

Common Packing Method

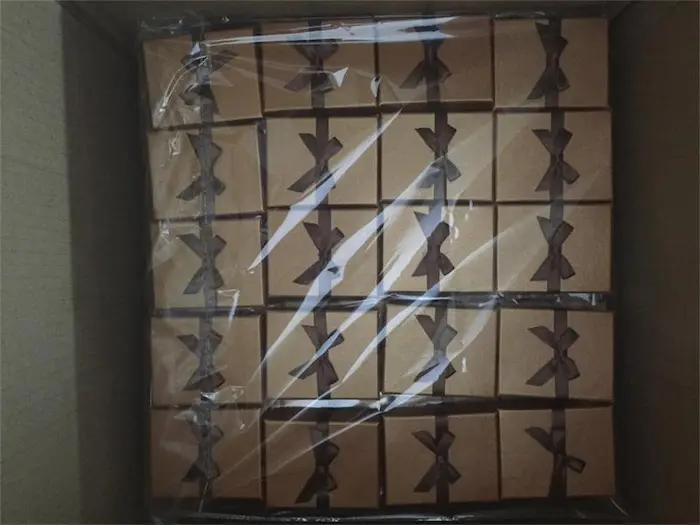

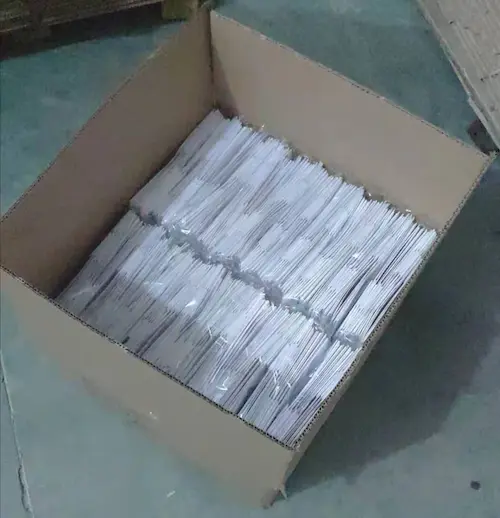

Safe Outer Packing

- Currugated Cartons

- Kraft Wrapping Paper

- Wood Cartons

Shipping Packing

- Plastic Pallet + Stretch Film

- Wood Pallet + Stretch Film

- Wood Packaging

Pros and Cons of outer packing for each packagings

| Packing Method | Material | Pros | Cons |

|---|---|---|---|

| Plastic Bag (PE Bag) | Polyethylene | ★ Low cost ($0.05–0.2/bag) | ▲ Non-recyclable |

| ★ Dust & moisture resistant | ▲ Fragile | ||

| Corrugated Outer Carton | 3-5 Ply Board | ★ High crush resistance | ▲ Adds volume/weight |

| ★ Customizable printing | ▲ Higher freight cost | ||

| Strapping (PP/PET) | Polypropylene/Polyester | ★ Low cost ($0.5–2/roll) | ▲ Requires tools |

| ★ Secures heavy loads | ▲ May damage edges | ||

| Pallet + Stretch Film | Wood/Plastic Pallet + PE Film | ★ Forklift-friendly | ▲ Requires storage space |

| ★ Prevents load shifting | ▲ Equipment investment | ||

| Kraft Paper Wrapping | Recycled Kraft | ★ Eco-friendly & biodegradable | ▲ Not waterproof |

| ★ High tear resistance | ▲ Plain appearance | ||

| Bubble Wrap Bag | PE Air Cushion | ★ Shock absorption | ▲ Plastic waste |

| ★ Lightweight | ▲ Higher cost ($0.5–3/bag) | ||

| Heat Seal Tape | Adhesive Composite | ★ Tamper-evident seal | ▲ Needs heat sealer |

| ★ Clean finish | ▲ Material restrictions |

5 Simple Steps to Select the Ideal Packing Method of Custom Packaging

Choosing the right packing method of custom packaging ensures your products like luxury paper bags and high-end paper boxes arrive safely, cost-effectively, and aligned with your brand values. Allen Paper Products (APP) breaks down the process into five actionable steps for custom packaging success.

Step 1: Define Your Product Requirements

- Fragility: Delicate items (glass, ceramics, electronics) need protective packing methods of custom packaging like foam, air cushions, or corrugated dividers.

- Size/Weight: Heavy or oversized items (furniture, machinery) require reinforced custom packaging with double-walled boxes or wooden crates.

- Value: High-value goods (luxury watches, jewelry) demand tamper-evident seals, RFID tags, or insurance-backed secure packing solutions.

Pro Tip: Test your packaging with a “drop test” to ensure durability for fragile items.

Step 2: Analyze Shipping Destinations & Logistics

- Domestic Shipping: Opt for cost-effective ground transport with recyclable mailers or standard boxes.

- International Shipping: Use climate-controlled packing methods of custom packaging for long hauls and comply with ISPM-15 wood regulations.

- Last-Mile Needs: Urban deliveries may require compact, lightweight custom packaging for easy handling; rural areas prioritize durability.

Pro Tip: Partner with carriers offering real-time tracking for high-priority shipments.

Step 3: Prioritize Sustainability & Brand Alignment

- Eco-Friendly Materials: Choose FSC-certified paper, biodegradable fillers, or reusable packing methods of custom packaging for eco-conscious audiences.

- Branding Integration: Use minimalist designs for luxury brands or bold, recyclable prints for eco-focused companies.

- Reusability: Design custom packaging that doubles as storage (e.g., magnetic-lock boxes) to enhance customer experience.

Pro Tip: 73% of consumers prefer brands with reusable or recyclable packaging—leverage this in your strategy.

Step 4: Evaluate Cost vs. Efficiency

- Budget Constraints: Use hybrid solutions like air freight for urgent orders and sea freight for bulk cost-effective packing methods of custom packaging.

- Volume Discounts: Order 500+ units of custom packaging to reduce per-unit costs by 25-40%.

- Hidden Costs: Factor in duties, insurance, and returns management for international shipments.

Pro Tip: APP’s bulk-ordering portal provides instant quotes for materials, labor, and logistics.

Step 5: Test & Optimize

- Prototype Testing: Simulate transit conditions (vibration, humidity) to refine protective packing methods of custom packaging.

- Customer Feedback: Survey users on unboxing experience—adjust designs for easier opening or sturdier builds.

- Continuous Improvement: Use AI analytics to track damage rates and shipping costs, refining methods quarterly.

Pro Tip: Integrate NFC tags into custom packaging to collect real-time feedback via QR code scans.

FAQ

Q1: What if my boxes are damaged during shipping?

A: Contact us immediately and share some photos and videos about the damage. We will call the shipping company to file a claim and propose compensation plans within 8 hours.

Q2: Are the materials recyclable and environmentally friendly?

A: Of course! All paper/cardboard is widely recyclable. Our processes comply with municipal recycling standards.

Q3: How to resolve quality issues with my delivered order?

A: Contact support within 24 hours of delivery. Provide photos, batch numbers, and defect details. We will investigate promptly and offer replacements, discounts, or refunds per our policy.

Q5: How to prevent scratches during production and shipping?

A: Each paper boxes are packed individually in a poly bag and shipped in sturdy strong outer cartons. Corrugated boxes are palletized and stretch-wrapped. Special scratch-resistant coatings (like soft-touch) are great helpful.

Q6: How to test and compare material thicknesses?

A: Folding cartons: Measured in points/pt or GSM (e.g., 18pt, 24pt, 300gsm). Corrugated: Measured by ECT (Edge Crush Test) rating or flute type/burst strength (e.g., B-Flute, 200# ECT). Consult our material spec sheets. The thickness betweet samples and mass production much be same!

Q7: How many days quality guaranteed? What to do if we're not happy for the quality?

A: 60-day quality guarantee. Unacceptable quality? We will promptly remake or provide a suitable resolution if the quality is not good enough.

Q4: Do you have warehousing and shipping services?

A: Yes! APP not only manufactures custom packaging but also ships orders directly. We also offer storage/consolidation services to reduce shipping costs.

Q8: Are the boxes and bags suitable for reuse?

A: Yes, our shipping boxes are able to reuse and recycling. It’s advised against using them again to ship products.