12 Common Box Inserts Introduction

Here’s a concise overview of 12 common box inserts, each described in one sentence with their key uses:

- Sponge (with velvet or paper), Soft sponge linings protect fragile items like glassware in gift boxes from scratches and impacts.

- EVA Foam, Lightweight EVA foam cushions items inside boxes; perfect for electronics or tool cases.

- EPE Insert,Pearl cotton (EPE) pads wrap delicate products in shipping boxes to prevent shock damage.

- Paper Cardboard, Sturdy cardstock forms dividers or trays in retail boxes to organize cosmetics or small parts.

- Corrugated Paper, Wavy corrugated paper adds structural support to product boxes, keeping items from shifting.

- Plastic Blister, Clear plastic blisters hold items visibly in place inside clamshell boxes for secure display.

- Tissue Paper, Thin tissue paper wraps clothes or gifts in boxes to prevent scratches and add presentation.

- Raffia Filler, Shredded confetti fills empty gaps in gift boxes, cushioning items while adding festive flair.

- Bubble Beads,Small bubble beads replace traditional wrap in custom wine boxes for lightweight, reusable cushioning.

- Satin Fabric, Smooth satin fabric lines box jewelry boxes inserts, giving a premium feel while protecting surfaces.

- Small Pouches, Mini pouches hold accessories like chargers inside boxes to keep components organized.

- Mini Pillows, Tiny fabric pillows secure watches or art in boxes, preventing movement during transit

| Product Name | Common Materials | Applications in Boxes | Advantages |

|---|---|---|---|

| Sponge | Polyurethane foam + velvet/paper | Luxury gift boxes, cosmetics, fragile items | Soft, shock-absorbing; velvet adds premium feel |

| EVA Foam | Ethylene-Vinyl Acetate foam | Electronics boxes, tool cases | Shockproof, waterproof; molds to any shape |

| EPE Insert | Expanded Polyethylene foam | Shipping boxes, fruit packaging | Lightweight, cheap; good cushioning |

| Paper Cardboard | 250g+ paper (e.g., kraft, metallic) | Retail boxes (cosmetics, food) | Printable, rigid dividers; eco-friendly |

| Corrugated Paper | Layered fluted paper | Food boxes, tea sets, electronics | Cheap, recyclable; structural support |

| Plastic Blister | PVC or PET sheets | Clamshell boxes (toys, cosmetics) | Clear visibility; custom-molded slots |

| Tissue Paper | Thin, soft paper | Clothing boxes, gift packaging | Scratch protection; cheap decorative fill |

| Raffia Filler | Shredded recycled paper | Gift boxes, party favors | Festive gap-filler; low cost |

| Bubble Beads | LDPE plastic beads | Lightweight product boxes | Reusable cushioning; space-efficient |

| Satin Fabric | Silk-like polyester | Jewelry boxes, premium gifts | Luxe look; protects polished surfaces |

| Small Pouches | Polyester/cotton | Subscription boxes (accessories, samples) | Organizes small parts; reusable |

| Mini Pillows | Fabric + filler (foam/fiber) | Watch boxes, art pieces | Prevents shifting; decorative touch |

| Product Name | Common Uses in Boxes | Key Considerations | Common Production Issues |

|---|---|---|---|

| Sponge | Luxury items, fragile protection | Match density to product weight; velvet shedding risks scratches | Uneven foam density; glue failure on velvet/paper layers |

| EVA Foam | Electronics, tool cases | Ventilate to reduce odor; avoid sharp edges that tear easily | Air bubbles during molding; trimming errors causing rough edges |

| EPE Insert | Shipping, lightweight items | Use high-density for heavy items; flattening gaps cause movement | Inconsistent foam expansion; weak seams splitting |

| Paper Cardboard | Retail dividers, cosmetics | Avoid moisture; reinforce folds for rigidity | Cutting misalignments; ink smudges on printed designs |

| Corrugated Paper | Food boxes, structural support | Seal fluted edges to prevent dust; weak if overly compressed | Delamination in humid conditions; uneven fluting |

| Plastic Blister | Toys, clamshell displays | Ensure uniform thickness; brittle corners crack in cold | Thin spots during thermoforming; trimming burrs |

| Tissue Paper | Gift wrapping, scratch prevention | Double-layer delicate items; tears if over-stretched | Inconsistent sheet thickness; dye transfer to products |

| Raffia Filler | Festive filler, lightweight gaps | Seal bags to contain mess; static makes clumping | Poor shredding consistency; color bleeding when damp |

| Bubble Beads | Void fill, lightweight cushioning | Use anti-static beads; spills if bags puncture | Seal leaks in pouches; bead size variation causing uneven protection |

| Satin Fabric | Jewelry lining, premium feel | Pre-wash to prevent stains; slippery surfaces shift items | Frayed edges; glue stains from adhesive application |

| Small Pouches | Accessory organization | Reinforce seams; loose threads jam zippers | Stitching gaps; misprinted logos |

| Mini Pillows | Securing watches, delicate art | Overfill less than 80% to avoid bursting | Uneven stuffing; fabric pilling during handling |

1. When are inserts needed in boxes?

The Inserts of Boxes are essential in boxes to protect breakables, secure valuables, and stop shifts during shipping.

2. Can boxes skip inserts to save money?

Yes—simple, non-fragile items (clothes, books) can skip custom inserts to cut costs, but risk damage if contents shift or lack cushioning.

3. How to save money on inserts of boxes?

Cut costs with reusable molds, eco-corrugated inserts, or bulk-buy designs.

4. How is insert height determined for protective box packaging?

Height equals product depth + cushioning gap (typically 3-8mm), ensuring items don’t touch the box lid when closed

5. Can insert colors be customized to match brand box jewelry boxes?

Yes—dyed foam or fabric-wrapped inserts (e.g., satin, velvet) align with brand colors, though custom hues add 10-20% cost

6. Do inserts of boxes support special finishes like foil stamping or UV coating?

Add shine, velvet feels, or foil to gift box lids for luxury—skip touch zones.

FAQ about Inserts of Boxes

Material Properties & Durability

Q1: Are EVA inserts truly eco-friendly for luxury boxes?

A: Only if certified REACH-compliant (0.1% max VOC). Standard EVA emits ethyl acetate. Opt for cross-linked PE foam (100% recyclable).

Q2: Will white PE foam inserts yellow in gift boxes stored in daylight?

A: Yes without UV stabilizers (add £0.08/unit). Light tests show faster yellowing over time.

Q3: Can cardboard inserts match foam’s cushioning for box Jewelry Boxes?

A: Only with honeycomb structures – 35 N/cm² crush strength vs PE foam’s 28 N/cm². Requires minimum 2.5mm wall thickness.

Structural Engineering

Q4: Maximum layers for foam inserts in electronics boxes?

A: 6 layers bonded with PU glue (peel strength >4.5 N/mm). Beyond this, stack tolerance exceeds ±0.3mm.

Q5: Can perforations in inserts reduce packaging costs?

A: Yes! Die-cut holes decrease material use 15-40% and lower shipping weight. Critical for ≥1000-unit orders.

Q6: Will crinkle paper inserts protect against 1.5m drops?

A: Only if layered 8+ sheets (150gsm basis weight). Single layer absorbs just 18G impact vs foam’s 45G.

Tailored & Matched

Q7: Can satin linings stain light-colored inserts?

A: Risk if dye migration > Grade 3 (ISO 105-E04). Always specify colorfast-treated fabric (+£0.12/unit).

Q8: Minimum order for custom soap boxes with vacuum-formed inserts?

A: Metal stamps cost much, so order 5000+ units. For smaller runs, use laser-cut PE foam box (MOQ 500).

Q9: Do plastic blister packs damage velvet inserts?

A: Yes, using static cling. Separate with 12μm anti-static film or use PETG instead of PVC.

Cost & Production Efficiency

Q10: Why TPU pillows cost 5x more than foam inserts?

A: TPU requires 6-minute cycle time vs 90s for foam molding. Worth the extra cost only for breakables or medical items.

Q11: Can pre-printed inserts skip secondary decoration?

A: Yes – but CMYK printing on kraft inserts of boxes loses ∆E>5 accuracy. Direct thermal transfer recommended instead.

Material Science Insights

Q12: Will EPS beads shift in transportation boxes?

A: Without anti-flow additive (0.5% paraffin), up to 15% settling occurs. Expandable foam pouches prevent this.

Q13: Humidity resistance of PLA vs PETG blister packs?

A: PLA warps at 85% RH while PETG maintains >90% structural integrity. Use desiccant cards in humid climates.

Green & Legal

Q14: Are paper shred inserts compliant with EU packaging regs?

A: Only if FSC-certified and chlorine-free. Recycled content must be traceable to meet EPR requirements.

Q15: Carbon footprint of corrugated inserts vs molded pulp?

A: Corrugated: 1.2kg CO₂/kg. Molded pulp: 0.8kg CO₂/kg (but needs 60-day soil tests)

Premium Finish Techniques

Q16: Can embossed logos adhere to flocked inserts of wine boxes?

A: Only with >600g/m² density flocking. Standard 300g/m² pile collapses under embossing pressure >8 MPa.

Q17: Gold foil on inserts of boxes – which materials hold best?

A: Art paper (adhesion 98%) vs coated cardboard (82%) vs kraft (68%). Hot foil stamping requires 120-150°C.

Hidden Risk Factors

Q18: Do PVC blisters damage sensitive contents?

A: Yes – outgassing phthalates can harm electronics/art. Use APET (0.3% max plasticizer) or acrylic instead.

Q19: Why do magnet closures fail with foam box?

A: Ferrite magnets lose 20-45% pull force through ≥2mm foam. Neodymium required at ≥6mm spacing.

Q20: Do velvet boxes cause static shocks?

A: Dry environments cause up to 15kV static. Mitigate with carbon fiber thread weave or ionized air treatment.

ALLEN LEE

Hi, I’m Allen Lee, the owner of Allenboxes.com, I’ve been in the packaging industry for over 20 years and running a factory in China that produce for 10+ years, and the purpose of this article is to share with you the knowledge related to packaging from a Chinese supplier’s perspective.

30 Common Sizes of Custom Boxes

4-step workflow to confirm Custom Box Sizes

Phase 1: Product & Dimension Fundamentals.

Phase 2: Box Type & Structural Design.

Phase 3: Budget-Driven Size Adjustments.

Phase 4: Prototyping & Refinement.

Top 8 Box Finishings

1. Foil Stamping2. Embossing/Debossing

3. Emboss + Foil (Combo Stamping)4. Spot UV

5. Glitter/Glitter Dust6. Flocking

7. Spot Embossing8. Die-Cut /Window Patching

12 Common Box Inserts Introduction

1.Sponge (with velvet or paper)2.EVA Foam 3.Pearl cotton (EPE)

4.Paper Cardboard 5.Corrugated Paper 6.Plastic Blister

7.Tissue Paper 8.Raffia Filler9.Bubble Beads

10.Satin Fabric,11.Small Pouches 12.Mini Pillows

5 tips about Materials of Paper Boxes

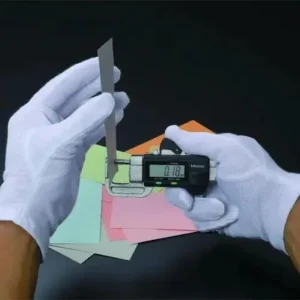

1.Measure thickness of raw material

2.Cut a 10x10cm sheet

3.Measure paper weight

4.Measure paper thickness

5.Check standard weight-thickness tables

How to control color discrepancy of paper boxes

1.Same materials /ink batch

2.Same printing machines & crew

3.Same finishing (lamination/coating)

4.Identical inspection tools + standards

5. Smart color choices (e.g., black + embossed logo)

6 steps to customize paper boxes

1. Design Box style, Colors, Logos.

2. Meet the budget.

3. Revisions & Prototyping

4. Final Approval & Refinement

5. Small-Batch Testing

6. Mass Production