How to choose the right box?

Selecting the ideal right box style is first step of starting custom packaging solutions. Crucial for both protecting your product and creating a great customer experience. Follow these steps to find the right box:

6 box types to choose

1. Rigid Gift Boxes

We call them Heaven & Earth Box (lid and base box). It separates two parts that fit snugly together. It usually use for luxury gifting, high-end cosmetics packaging, and premium electronics packaging (like smartphones), emphasizing unboxing experiences and brand prestige.

2. Drawer Boxes

Drawer Box consists of an outer sleeve and an inner tray that slides smoothly in and out like a drawer. The standout feature is its unique sliding mechanism, offering an interactive, engaging, and protective way to reveal the contents.

3. Book Style Boxes

This box opens like a book and often has magnetic closure. It uses for jewelry boxes, special collectibles, and high-end apparel packaging.

4. Folding Boxes

Folding Boxes can be stored and shipped flat. They storage little space until glued and assembled. They use for retail packaging, like cosmetics and electronics, apparel and shoe packaging. They are also a popular choice for eco-friendly paperboard solutions.

5. Card Board Boxes

Card Board Boxes are lightweight and made from thinner paper. They offer durability and some flexibility. They balance the sturdiness of rigid boxes with the cost-effectiveness of folding cartons.

6. Mailer Boxes

Mailer Boxes, also known as Airplane Boxes, are strong and self-locking. Popular custom shipping boxes for e-commerc. Key features include locking tabs or easy sealing.

4 steps to Choose the Right Box for Your Product

1.Assess Boxes Required Dimensions:

Consider its shape, product size (Length x Width x Height), weight, fragility, and orientation (how it will sit inside the box). Calculate the box dimensions needed. Add the thickness of the box material itself to determine the final external dimensions. Remember, shipping costs are heavily influenced by these external dimensions (dimensional weight).

2. Explore Box Style and Meet Budget:

Share your preferred box styles. Cost Breakdown by Unit Cost and Shipping Cost (Critical). Shipping in flat and shipping by sea save much. But the handmade of folding box is higher.

3.Refine Selection & Optimize for Cost:

Revisit Choices by Comparing your preferred box styles against the budget. Have the best balance and final idea of box style.

4. Test with customized Samples or a small-batch production:

Request cusomized packaging samples to check if you satisfy all info included size, printing, materials, durability, and so on. Then start a small trial order to test the market. Get feedback from your fulfillment team and customers. Test shipping performance across several packages before committing to large volumes.

When need to choose the right box

1. When Shipping Costs Are Too High

Switch rigid boxes to corrugated mailer boxes or folding card board boxes to cut freight costs by 30-60%. Folding magnetic handmade boxes are the better choice for luxury apparel brand.

2. When Warehouse Space Is Limited

Use flat-packed folding magnetic boxes or paper card board boxes to store 5x more units in the same warehouse area. Folding Boxes are luxury and cartons are economic for different products and markets.

3. When Product Protection Is Critical

Electronics or ceramics use mailer boxes with foam inserts, or rigid boxes with EVA inserts for luxury fragility. The safety of fragile products is more important than the cost of the outer packaging.

4. When Premium Branding is Essential

Perfume brands use drawer boxes with foil stamping for unboxing prestige. High-end custom boxes combined with impressive finishing, can bring more profits and increase the selling price of the products.

5. When Balancing Cost & Quality

20−50 skincare sets use cardstock boxes with spot UV for affordable luxury. Changing the box style is an effective way to reduce the cost of custom packaging.

6. When Eco-Friendliness Matters

The corrugated boxes and card board boxes are even more environmentally friendly. They are without any lamination, magnets, other accessories. Although all the paper boxes are recyclable.

Why we choose the box?

Offers exceptional structural strength and a luxurious, high-end feel ideal for premium products and enhancing brand perception. And provides superior protection for fragile items and creates an impressive, memorable unboxing experience.

2. High end Drawer Box

The unique, engaging sliding mechanism are impressive. And ehances the brand and product presentation.

Delivers a dramatic, elegant presentation upon opening, mimicking a book and ideal for storytelling branding. And the hinged lid offers easy access and displays the product beautifully, often secured with magnetic closures.

Extremely cost-effective to produce and ship flat, significantly reducing shipping volume and storage space. And highly versatile for printing complex graphics and adapting to diverse product shapes using die-cutting.

5. Recycle Card Board Box

Balances better sturdiness and a more premium presentation than folding cartons at a lower cost than rigid boxes. And lightweight yet strong enough for many non-fragile items, offering excellent print quality for branding.

6. Wholesale Mailer Box

Engineered with strong, durable corrugated construction specifically for safe, economical e-commerce shipping. And features integrated locking tabs or tear strips for easy assembly and customer opening, enhancing convenience.

Wholesale Paper Boxes, Unbeatable Value

Contact us freely for more info. Or choose the right box style also discuss more about the right packaging solutions with us together. Email us for a Free customized sample today!

ALLEN LEE

Hi, I’m Allen Lee, the owner of Allenboxes.com, I’ve been in the packaging industry for over 20 years and running a factory in China that produce for 10+ years, and the purpose of this article is to share with you the knowledge related to packaging from a Chinese supplier’s perspective.

30 Common Sizes of Custom Boxes

4-step workflow to confirm Custom Box Sizes

Phase 1: Product & Dimension Fundamentals.

Phase 2: Box Type & Structural Design.

Phase 3: Budget-Driven Size Adjustments.

Phase 4: Prototyping & Refinement.

Top 8 Box Finishings

1. Foil Stamping2. Embossing/Debossing

3. Emboss + Foil (Combo Stamping)4. Spot UV

5. Glitter/Glitter Dust6. Flocking

7. Spot Embossing8. Die-Cut /Window Patching

12 Common Box Inserts Introduction

1.Sponge (with velvet or paper)2.EVA Foam 3.Pearl cotton (EPE)

4.Paper Cardboard 5.Corrugated Paper 6.Plastic Blister

7.Tissue Paper 8.Raffia Filler9.Bubble Beads

10.Satin Fabric,11.Small Pouches 12.Mini Pillows

5 tips about Materials of Paper Boxes

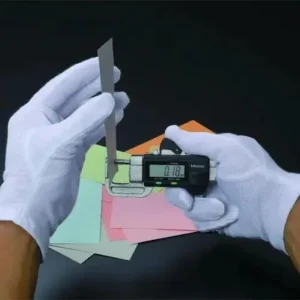

1.Measure thickness of raw material

2.Cut a 10x10cm sheet

3.Measure paper weight

4.Measure paper thickness

5.Check standard weight-thickness tables

How to control color discrepancy of paper boxes

1.Same materials /ink batch

2.Same printing machines & crew

3.Same finishing (lamination/coating)

4.Identical inspection tools + standards

5. Smart color choices (e.g., black + embossed logo)

6 steps to customize paper boxes

1. Design Box style, Colors, Logos.

2. Meet the budget.

3. Revisions & Prototyping

4. Final Approval & Refinement

5. Small-Batch Testing

6. Mass Production