How to control color discrepancy of paper boxes?

What is color discrepancy?

Difference between designed colors and final printed results or each batch of products. Such as hue variations or saturation differences.

Can color discrepancy be 100% avoided in custom boxes?

100% impossible! But below are 5 Color Discrepancy Solutions for paper boxes:

- Same materials /ink batch

- Same printing machines & crew

- Same finishing (lamination/coating)

- Identical inspection tools + standards

- Smart color choices (e.g., black + embossed logo)

- Double-Sided Coated Paper: Offers superior color stability because uniform ink absorption on both sides. Minimize color shifts in printed paper boxes—ideal for high-graphic designs.

- Single-Sided Coated Paper: Color stability is lower on the uncoated side, leading to potential discrepancies in printed paper boxes requiring double-sided visibility.

- White Kraft Paper: It is eco friendly but its bumpy surface may make colors look slightly different. For steady color in customized paper boxes, always use matte varnishing.

- Wood Free Paper: Provides consistent whiteness and smoothness. It reduces color deviation in custom boxes with logo for luxury packaging like rigid gift boxes christmas.

- Grey Cardboard Paper: Single-sided coating limits stability. Requires UV/matte finishes to counter yellow undertones and humidity sensitivity (ΔE≤2.5) for budget booklet box.

- Special Art Papers (e.g., textured/foiled): High risk on color shifts. For steady colors, use Pantone inks and UV finish for magnetic gift boxes wholesale.

Common colors and printing types

1. Color Systems for Paper Boxes

CMYK: Use CMYK for colorful designs. Ideal for art paper and coated paper because of smooth surfaces that retain ink detail.

Pantone colors: Matches brand-specific colors (e.g., logos) with precision. Best for kraft paper and cardboard, where color consistency is critical.

Special Inks: Metallic gold/silver. Or hot stamping or screen printing, often on luxury rigid boxes or textured paper boxes.

2. Common Printing Techniques

Offset Printing on Coated paper, art board for High-detail cosmetic packaging boxes.

Flexographic on Corrugated cardboard for kraft for Shipping boxes, eco-mailers. Fast drying, cost-effective for bulk.

Silk Screen on Rigid boards and leather art paper for luxury watch boxes, box jewelry boxes. Thick ink layers and tactile effects.

Digital Printing on Light weight papers (≤300gsm) for Small-batch custom boxes with logo. No plates needed and quick turnaround.

3. Surface Finishes

Lamination Gloss/Matte: Adds durability and shine. Used on coated paper for cosmetics or white cardstock for luxury goods.

Spot UV: Creates glossy contrasts on matte laminated surfaces. Ideal for highlighting logos on gift boxes for presents.

Embossing / Debossing: Works best on thick paper (e.g., 400gsm) for premium packaging.

Hot Foil: Applies metallic gold, silver on logos. Requires smooth art paper or kraft paper for adhesion.

Which printing is suitable?

- UV printing keeps colors super steady. UV lamps dry inks fast, locking colors perfectly onto printed paper boxes. This prevents fading.

- Hot foil stamping gives almost no color change on custom boxes with logo. Why? The foil colors are in stock to choose.

- Spot UV adds a glossy shield over ink. It prevents sun/air damage, so colors stay truer for longer on your boxes.

- Flexo printing gives pretty steady colors on printed paper boxes, especially with Pantone colors. But since inks soak into paper, tiny color shifts might happen.

- Offset printing gives steady color in custom gift boxes. It perfectly balances ink and water while matching colors exactly.

20 methods to minimize color discrepancies of printed gift boxes

- Use identical reference samples and production batches for boxes cardboard boxes to eliminate batch-to-batch variations.

- Produce all custom boxes with logo on the same printing press within one factory to avoid machine-specific deviations.

- Use the same person for all customized gift box jobs = steady work.

- Stick to same ink brand + mix to avoid color surprises.

- Keep same heat/moisture levels to keep ink steady.

- Ensure uniform substrate whiteness (e.g., paper grade) across all booklet box batches.

- Apply identical finishing treatments (e.g., gloss/matte lamination, foil stamping) to avoid surface-effect variations.

- Set ΔE thresholds (e.g., ΔE<2) for measurable tolerance and visual approval for customized paper gift boxes acceptance.

- Always check colors under the same controlled light.

- Stick with the same tools and trained team for trustworthy custom branded boxes checks.

- Implement Pantone Matching System (PMS) for custom gift boxes to ensure spot-color accuracy and brand consistency.

- Apply ICC profiles to standardize color conversion across devices for customized paper packaging boxes.

- Calibrate printers/monitors weekly to maintain device accuracy for luxury paper boxes design and proofing.

- Test samples first to see how ink works with your paper before making custom vape boxes.

- Validate colors via physical hard proofs pre-verify print outcomes.

- Optimize print pressure settings to ensure uniform ink layering on gift boxes christmas.

- Always clean rollers and plates to stop ink messes during custom paper box runs.

- Control water mix in offset printing to stop ink problems on wholesale boxes.

- Build a Pantone/library database for quick color retrieval in brand paper boxes work flows.

- Share color standards with ink/paper suppliers to align material properties.

ALLEN LEE

Hi, I’m Allen Lee, the owner of Allenboxes.com, I’ve been in the packaging industry for over 20 years and running a factory in China that produce for 10+ years, and the purpose of this article is to share with you the knowledge related to packaging from a Chinese supplier’s perspective.

30 Common Sizes of Custom Boxes

4-step workflow to confirm Custom Box Sizes

Phase 1: Product & Dimension Fundamentals.

Phase 2: Box Type & Structural Design.

Phase 3: Budget-Driven Size Adjustments.

Phase 4: Prototyping & Refinement.

Top 8 Box Finishings

1. Foil Stamping2. Embossing/Debossing

3. Emboss + Foil (Combo Stamping)4. Spot UV

5. Glitter/Glitter Dust6. Flocking

7. Spot Embossing8. Die-Cut /Window Patching

12 Common Box Inserts Introduction

1.Sponge (with velvet or paper)2.EVA Foam 3.Pearl cotton (EPE)

4.Paper Cardboard 5.Corrugated Paper 6.Plastic Blister

7.Tissue Paper 8.Raffia Filler9.Bubble Beads

10.Satin Fabric,11.Small Pouches 12.Mini Pillows

5 tips about Materials of Paper Boxes

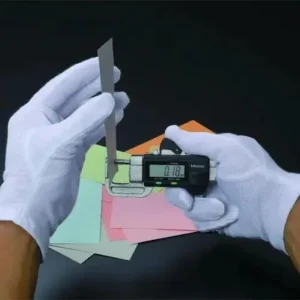

1.Measure thickness of raw material

2.Cut a 10x10cm sheet

3.Measure paper weight

4.Measure paper thickness

5.Check standard weight-thickness tables

How to control color discrepancy of paper boxes

1.Same materials /ink batch

2.Same printing machines & crew

3.Same finishing (lamination/coating)

4.Identical inspection tools + standards

5. Smart color choices (e.g., black + embossed logo)

6 steps to customize paper boxes

1. Design Box style, Colors, Logos.

2. Meet the budget.

3. Revisions & Prototyping

4. Final Approval & Refinement

5. Small-Batch Testing

6. Mass Production