Common Sizes of Custom Boxes

| Product Name | Product (L×W×H) | Box Size (L×W×H) |

|---|---|---|

| Smartphone | 15×7×1 cm | 18×9×4 cm |

| Jewelry Ring | 5×5×2 cm | 8×8×5 cm |

| Lipstick | 8×2×2 cm | 10×4×4 cm |

| Sneakers (Men’s) | 30×20×12 cm | 35×25×15 cm |

| Hardcover Book | 23×15×4 cm | 26×18×6 cm |

| Wine Bottle | 8×8×30 cm | 11×11×35 cm |

| Tablet | 24×16×0.8 cm | 27×19×4 cm |

| Coffee Mug | 9×9×10 cm | 12×12×14 cm |

| T-Shirt (Folded) | 25×20×3 cm | 28×23×6 cm |

| Scented Candle | 7×7×7 cm | 10×10×10 cm |

| Wireless Earbuds | 6×4×3 cm | 9×7×6 cm |

| Perfume (50ml) | 6×6×12 cm | 9×9×15 cm |

| Action Figure | 15×5×5 cm | 18×8×8 cm |

| Yoga Mat | 60×5×5 cm | 65×9×9 cm |

| Laptop (13″) | 30×21×2 cm | 35×25×6 cm |

| Pillow | 40×40×10 cm | 45×45×15 cm |

| Board Game | 25×25×6 cm | 28×28×8 cm |

| Makeup Palette | 18×9×2 cm | 21×12×5 cm |

| Bluetooth Speaker | 15×8×8 cm | 18×11×11 cm |

| Desk Lamp | 20×20×35 cm | 25×25×40 cm |

| Vitamin Bottle | 5×5×10 cm | 8×8×13 cm |

| Cutting Board | 30×20×2 cm | 35×25×5 cm |

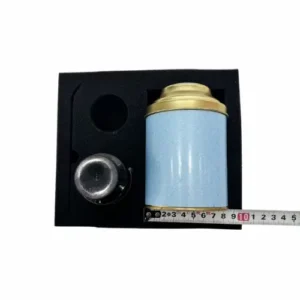

| Tea Tin Set | 10×10×15 cm | 13×13×18 cm |

| Throw Blanket | 35×35×10 cm | 40×40×15 cm |

| Puzzle (1000pcs) | 25×25×5 cm | 28×28×7 cm |

| Water Bottle | 8×8×25 cm | 11×11×30 cm |

| Gift Card | 8×5×0.2 cm | 10×7×2 cm |

| Hand Sanitizer | 7×4×4 cm (100ml) | 10×7×7 cm |

| Dog Toy | 10×5×5 cm | 13×8×8 cm |

| Plant Pot (Small) | 12×12×12 cm | 15×15×15 cm |

Phase 1: Product & Dimension Fundamentals

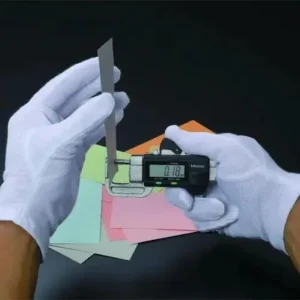

Measure Product Dimensions. Accurately record the product’s length, width, and height to the nearest 0.125 inch (3mm) using calipers or a ruler. For irregular shapes, capture the maximum dimensions in each axis .

Example: A 15×10×5cm smart phone requires measuring its longest edges, including protruding buttons.

Include Protective Materials

Add buffer space for inserts (e.g., foam, dividers): 1–2cm per dimension. Calculate total internal space as:

Internal Box Size = Product Size + Insert Thickness + 5–10mm movement buffer .

Determine Quantity per Box

Specify unit count per box (e.g., 12 lipsticks). Multiply product dimensions by quantity, adding 3–5mm spacing between items to prevent contact damage .

Phase 2: Box Type & Structural Design

Select Box Style (FEFCO Standard)

0201 (RSC): Universal shipping box (85% usage) .

0427 (Pizza-style): Flat-pack retail trays .

Auto-Lock/Straight Tuck End: For e-commerce; max L+W ≤9.875″ .

Define Internal vs. External Dimensions

Internal: Space for the product (critical for fit).

External: Total box size (for shipping costs). Add board thickness (e.g., 3mm for B-flute corrugated) to internal dimensions .

Calculate Dimensional Weight

Use carrier formula: (L×W×H)/DIM divisor (e.g., UPS: 139). Optimize to avoid oversize fees; target ≤10% empty space .

Material & Cost Balancing

Budget-saving: Use single-wall corrugated (vs. double-wall) or recycled greyboard (40% cheaper than white core) .

Premium: Opt for coated art paper + spot UV for ≤15% cost increase vs. foil stamping .

Phase 3: Budget-Driven Size Adjustments

Reduce Board Grade

Downgrade from 300gsm to 200gsm kraft if product weight <1kg; saves 20% material cost .

Flatten Design for Logistics

Modify 3D shapes to flat-pack (e.g., FEFCO 0427) to cut storage/transport costs by 30% .

Minimize Print Complexity

Use 1–2 Pantone colors (not CMYK simulations) and avoid lamination where possible; reduces cost by 15% .

Phase 4: Prototyping & Refinement

Request 3D Mockup

Validate structural integrity via a die-line prototype. Check critical tolerances:

Flap closure alignment (±0.5mm).

Glue tab positioning (≥10mm overlap) .

Perform Functional Testing

Drop-test: From 1m height (ISTA 1A standard) to confirm crush resistance .

Compression test: Apply 1.5× product weight for 48hrs; deformation ≤2% is acceptable .

Adjust for Production Feasibility

Tooling limits: Ensure cuts/creases align with die-cutter tolerances (±0.3mm).

Ink adhesion: Test on selected board; uncoated kraft may require primer for ΔE≤3 color accuracy .

Finalize Eco & Compliance Checks

Confirm recyclability of materials (e.g., water-based coatings only).

Validate size compliance with target carrier (e.g., DHL max: 120×60×60cm) .

1. Why Make Paper Boxes Smaller

Smaller boxes cut material waste by up to 30%. They lower shipping costs by fitting more in trucks, avoiding size-based fees.

Compact designs reduce empty space—no bubble wrap needed. Saves 15–25% on packaging. Works with e-commerce “right-size” tools. Also boosts recycling: less bulk, easier to discard.

2. Why Make Paper Boxes Larger

Bigger boxes fit protectors (like foam) for fragile electronics—cutting damage by 40% and fewer returns. Extra space lets you bundle items (gift sets/subscriptions), giving better unboxing and brand image while saving on shipping. Big designs can serve as storage or as planters. This helps them last longer and keeps customers interested.

3. Why Make Paper Boxes Exact-Fit

Precise sizing ensures optimal structural integrity, where ≤5mm buffers prevent product movement during transit—critical for ISTA 1A compliance and minimizing compression failures . ”Zero-waste” dimensions align with automated packing systems, boosting efficiency by 20% through standardized workflows (e.g., auto-boxing machines) . Exact-fit boxes maximize sustainability, using 100% recycled materials with minimal excess, directly lowering carbon footprints and qualifying for eco-tax incentives .

4. Why Product Damage Occurs with Oversized Boxes

Oversized boxes cause shifting and crashing damage (up to 40% risk). They also trigger size-based fees, raising shipping costs.

5. Why Small Box Sizes May Limit Pricing Potential

Small packages make products seem less valuable. They look cheap and damage your luxury image, so people can’t pay higher prices for gifts or high-end items.

6. The Balance Between Size, Protection & Value

Right-sized boxes secure items and elevate brands. They stop sliding damage and boost unboxing joy—letting brands charge 20% more for a premium look.

1. Book-Style Box (Inner) + Mailer Box (Outer)

Use Case: Luxury items (e.g., jewelry, watches) requiring high-end presentation and shipping protection.

Design Workflow:

Inner Book-Style Box:

Dimensions: Inner box = Product dimensions + 5mm buffer per side .

Example: For a 10×8×3cm product → Inner box = 10.5×8.5×3.5cm.

Structure: Use rigid cardboard (1.5–2mm thickness) with magnetic closure or ribbon seal for premium feel .

Customization: Add foil stamping/embossing for branding; include fitted foam inserts to prevent movement .

Outer Mailer Box:

Dimensions: Outer box = Inner box size + 15–20mm per side + filler thickness (e.g., bubble wrap) .

Example: Inner box 10.5×8.5×3.5cm → Outer box = 12.5×10.5×6cm.

Material: Corrugated cardboard (B-flute, 3mm) for crush resistance .

Optimization:

Reduce void space with crumpled paper or air pillows.

Print carrier-compliant labels (e.g., DHL barcode zones).

Prototype Testing: Drop-test from 1m height (ISTA 1A) to validate protection .

2. Card Box (Inner) + Folding Boxes (Outer)

Use Case: Small items (e.g., electronics, cosmetics) needing compact organization.

Design Workflow:

Inner Card Box:

Dimensions: Match product exactly (e.g., 9×6×2cm for a smartphone accessory) .

Structure: Use chipboard (1mm) with auto-lock tabs; include PVC windows for product visibility .

Inserts: Use PET trays or cardboard to separate items.

Outer Folding Carton:

Dimensions: Outer carton = Inner box size × quantity + 10mm per unit spacing.

Example: 4 inner boxes (9×6×2cm) → Outer carton = 18.5×12.5×2.2cm (2×2 grid) .

Material: Recycled paperboard (250gsm) with gloss lamination for weather resistance.

Closure: Use tuck flaps or adhesive seals for easy assembly .

Eco-friendliness: Choose soy inks and uncoated kraft paper to lessen ecological effects.

3. Book-Style Box (Inner) + Paper Bag (Outer)

Use Case: Retail/gift items (e.g., books, apparel) requiring portability and aesthetic appeal.

Design Workflow:

Inner Book-Style Box:

Dimensions: Same as Scenario 1, but add handle cutouts or ribbon slots for carrying .

Finish: Textured surfaces (e.g., linen embossing) + spot UV for tactile luxury .

Outer Paper Bag:

Dimensions: Bag width/depth = Inner box length/width + 15mm; height = Inner box height + 50mm .

Example: Inner box 12×9×4cm → Bag = 14×11×9cm.

Material: Kraft paper (180gsm) with reinforced base and twisted paper handles.

Branding: Print minimalist logos; use biodegradable hot-melt adhesives .

User Experience: Include tissue paper and thank-you cards for “Instagrammable” unboxing .

Cross-Scenario Engineering Principles

Dimensional Synergy:

Maintain 3–5mm gap between inner/outer layers to prevent compression damage .

For irregular products, use custom inserts (e.g., thermoformed foam) to stabilize contents .

Cost & Efficiency:

Mailer Boxes: Ideal for shipping; optimize DIM weight by sizing down outer boxes .

Folding Cartons: Reduce glue tabs for faster assembly; use flat-pack designs to cut storage by 40% .

Paper Bags: Prioritize handle tensile strength (>5kg) for heavy items .

Compliance & Sustainability:

Ensure outer packaging meets carrier max dimensions (e.g., FedEx box sizes: 120×60×60cm) .

Use FSC-certified materials + water-based coatings for recyclability .

Carrier Compliance & Optimization

Q: What FedEx small box size avoids DIM penalties?

A: ≤41×36×15cm (0.022m³) – stays under 2.5kg DIM weight threshold. Exceeding adds $4.15+ surcharges.

Q: Optimal UPS box lengthfor apparel bundles?

A: ≤53cm – fits standard conveyor systems. Beyond 56cm triggers $12 oversize fees.

Material Science Insights

Q: Why do corrugated boxesexpand 0.8% post-production?

A: Flute relaxation under humidity. Pre-shrink materials or specify humidity-controlled drying (±0.3% tolerance).

Q: Minimum cardboard sizefor electronics packaging?

A: 32 ECT B-flute (3mm) with ≥2cm foam buffer – survives 1.2m drops (ISTA 3A).

Retail & Display Optimization

Q: Ideal shoe box size for shelf impact?

A: 30×20×13cm (industry std.) – fits 92% of retail fixtures. Custom size incur +15% stocking fees.

Q: Personal bag dimensions for countertop displays?

A: 18×12×8cm – maximizes impulse buys. Exceeding 20cm depth reduces visibility 40%.

Subscription & E-commerce

Q: Best size pack for monthly subscription boxes?

A: 38×28×10cm – holds 3-5 items while staying under USPS Priority 2kg tier ($9.50 shipping).

Q: FedEx carton sizes for apparel bundles?

A: Use 48×32×6cm flat-rate – fits 5 garments at $14.35 (saves 22% vs dimensional).

Specialty Packaging

Q: Nike box size standardization benefits?

A: 38×28×15cm reduces:

Warehouse slots by 30%

Shipping damage 18%

Tooling costs 65%

Q: Bag dimensionsfor luxury shoes?

A: 42×30cm dust bags with 5mm felt padding – prevents scuffs during transit.

Cost Engineering

Q: How measuring box size cuts freight 27%?

A: Optimize to carrier thresholds:

FedEx Ground: ≤ 0.25m³

DHL eCommerce: ≤ 42×35×25cm

USPS: ≤ 61×46×46cm

Q: Stock size vs custom size cost difference?

A:

Parameter

Stock

Custom

Setup Fee

$0

$350+

Unit Cost

$0.85

$1.20

Lead Time

3 days

21 days

Compliance & Regulations

Q: Personal bag sizefor airline compliance?

A: 45×35×20cm (IATA carry-on) – critical for travel accessory packaging.

Q: FedEx box sizes for lithium batteries?

A: ≤30kg gross weight + ≥1.5cm wall thickness – meets IATA PI 965 Section II.

Material Specifications

Q: Standard cardboard sizes for pallet efficiency?

A: 60×40cm Euro-pallet:

80 boxes @ 30×20×10cm

120 boxes @ 20×20×10cm

Maximizes 92% space utilization.

Q: Size of packagingfor OLED TVs?

A: Screen size + 15cm each side with ≥5cm EPS foam – prevents flex damage during transit.

Printing & Branding

Q: Minimum card stock sizes for inserts?

A: 9×5cm for QR codes | 12×7cm for legible text (4pt font).

Q: Box lengthlimits for hot foil stamping?

A: ≤60cm – beyond requires segmented dies (+$220 setup).

Sustainability & Waste Reduction

Q: How packaging size affects carbon footprint?

A: Reducing 10% dimensions = 17% lower emissions (material + shipping).

Q: Optimal bag size for e-commerce?

A: Mailers ≤ 35×28cm use 38% less plastic than boxes while passing 1m drop tests.

ALLEN LEE

Hi, I’m Allen Lee, the owner of Allenboxes.com, I’ve been in the packaging industry for over 20 years and running a factory in China that produce for 10+ years, and the purpose of this article is to share with you the knowledge related to packaging from a Chinese supplier’s perspective.

Common Sizes of Custom Boxes

4-step workflow to confirm custom paper box dimensions

Phase 1: Product & Dimension Fundamentals.

Phase 2: Box Type & Structural Design.

Phase 3: Budget-Driven Size Adjustments.

Phase 4: Prototyping & Refinement.

4 steps to choose the right box

1.Assess Boxes Required Dimensions

2. Explore Box Style and Meet Budget

3.Refine Selection & Optimize for Cost

4. Test with customized Samples or a small-batch production:

3 Steps to Save Shipping costs

Step 1: Use foldable boxes instead of two-piece rigid boxes.

Step 2: Customize to a smaller box. And Order early to use economy ocean freight instead of air.

Step 3: Select Door to door service include all taxes and freight.

6 steps to customize paper boxes

1. Design Box style, Colors, Logos.

2. Meet the budget.

3. Revisions & Prototyping

4. Final Approval & Refinement

5. Small-Batch Testing

6. Mass Production

How to control color discrepancy of paper boxes

1.Same materials /ink batch

2.Same printing machines & crew

3.Same finishing (lamination/coating)

4.Identical inspection tools + standards

5. Smart color choices (e.g., black + embossed logo)

5 tips about Materials of Paper Boxes

1.Measure thickness of raw material

2.Cut a 10x10cm sheet

3.Measure paper weight

4.Measure paper thickness

5.Check standard weight-thickness tables