Printing on custom packaging

Printing on custom packaging: Cost Guide about Pantone vs CMYK printing. APP’s guide compares color accuracy, cost & hybrid solutions. Color Accuracy Showdown: Pantone Consistency vs CMYK Flexibility. Request more info and free printed samples with MOQ 0!

Printing on white paper

Colors of original paper

Printing on custom packaging CMYK VS Pantone

- Pantone uses pre-mixed inks for precise, consistent colors (ideal for logos/branding), while CMYK blends cyan, magenta, yellow, and black to create hues (cost-effective for multi-color designs).

- Color accuracy: Pantone guarantees exact matches across materials; CMYK may vary due to ink mixing and printer calibration.

- Cost and complexity: Pantone requires separate plates/inks, raising costs; CMYK uses standardized process printing for affordability.

- Application: Choose Pantone for critical brand colors, metallic/fluorescent effects, or single-color projects; opt for CMYK for photorealistic prints or budget-sensitive bulk jobs.

- Hybrid solutions: Combine both (e.g., Pantone for key brand elements + CMYK for background art) to balance vibrancy, consistency, and cost.

Physically impossible! But control it with these 5 proven solutions:

- Source identical material/ink batches

- Use consistent printing equipment & team

- Apply uniform finishing (lamination/coating)

- Maintain identical inspection standards

- Choose stable colors (e.g., black + embossed logo)

1. Standardize Color Proofing

- Pantone Matching: Require physical Pantone swatches for all brand colors

- Digital Mockups: Share screen-accurate proofs with suppliers before production

- Batch Alignment: Use master reference samples across all printing runs

2. Optimize Materials & Techniques

- Paper Choice: Select coated stocks for sharper color reproduction

- Print Method: Use offset printing for solid colors; avoid CMYK blends for critical hues

- Ink System: Specify single-pigment inks to minimize metamerism

3. Implement Batch Testing

- Lighting Checks: Verify colors under D65 daylight + store lighting

- Supplier Calibration: Jointly adjust press settings for substrate absorption rates

- ΔE Monitoring: Track color deviation (accept ≤1.5 ΔE)

4. Post-Production Verification

- Spectrophotometer Scans: Measure 3+ random boxes per batch

- QC Light Booth: Check for metamerism (color shifts under different lights)

- Document Variances: Create visual tolerance guides for acceptable ranges

5. Continuous Improvement Loop

- Color Database: Log all batch results with photos/measurements

- Quarterly Reviews: Analyze trends with suppliers to refine processes

- Preventive Adjustments: Modify artwork trapping/overprints based on historical data

10 FAQ of Printing

Plate & Setup Costs

Q: Do custom packaging boxes require CTP plates? Cost?

A: Offset printing requires CTP plates: $85-120/color (size-dependent). Digital printing eliminates plate fees.Q: Is makeready fee charged for printed boxes?

A: Yes! $220-380 per job covers:Ink calibration

Registration alignment

Waste sheets (first 100-300 sheets)

Color Systems & Pricing

Q: CMYK vs Pantone cost difference for custom boxes with logo?

A:Method Setup Cost Per Unit Cost CMYK $0 $0.003/cm² Pantone Spot $120/color $0.007/cm² 4C + 1 Pantone $120 $0.009/cm² Q: Premium custom color options beyond Pantone?

A: Metallic inks (+40%), fluorescent pigments (+65%), thermochromic (+$0.08/cm²) – MOQ 5,000+ units.

Color Accuracy Control

Q: How to reduce color variance in custom print runs?

A: Implement:G7 calibration (ΔE<1.5)

Spectrophotometer QC every 500 sheets

Standardized D50 lighting for approvals

Reduces rejects by 83%

Q: CMYK to Pantone conversion accuracy?

A: 85% match within ΔE<3.0 – critical colors (logos) require spot Pantone for ΔE<1.0 precision.

Material-Specific Challenges

Q: Why do kraft customised boxes show color shifts?

A: Brown substrate alters hues. Solutions:White underbase layer (+$0.05/unit)

Double-hit printing

Pantone 873C/874C (optimized for kraft)

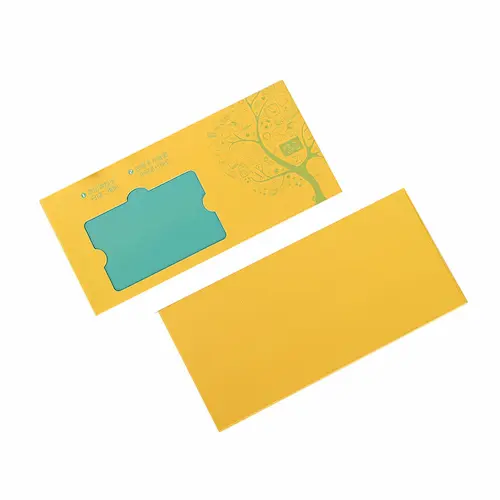

Q: Envelope printing color consistency issues?

A: Woven textures cause dot gain variations. Use:Smooth-coated envelopes

Reduced ink density (280% max TAC)

Digital printing (avoids dot gain)

Cross-Platform Branding

Q: Matching custom business cards to printed boxes?

A: Require:Shared ICC profile

Identical substrate whiteness (≥92 CIE)

Batch-controlled inks

Achieves ΔE<1.5 across materials

Q: Custom card printing for packaging inserts?

A: Use same Pantone references as main box – specify exact paper stock (e.g., 270gsm Mohawk Superfine).