Top 8 Box Finishings

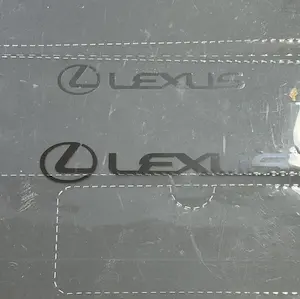

1. Foil Stamping

Foil hot stamping applies metallic to surfaces using heat and pressure. Create a reflective finish like gold logos or text .

It enhances brand recognition. Commonly used on premium packaging and book covers. Premium business cards elevate brand perception.

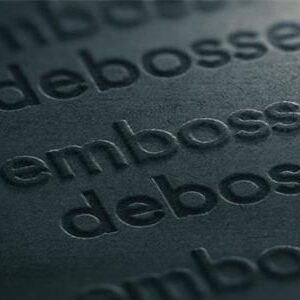

2. Embossing Debossing

Embossing lifts designs above the surface. This adds a tactile feel for emboss logos or patterns using custom dies and high pressure. Debossing indents designs into the material, offering subtle sophistication while preserving the reverse side’s usability, ideal for minimalist branding .

3. Emboss + Foil Stamping (“Combo Stamping”)

This combines embossing with foil application, where raised areas are simultaneously foil-stamped to create a metallic 3D effect . It creates a strong visual effect for luxury products, like cosmetics or special packaging, by combining texture and shine.

4. Spot UV

Spot UV adds shiny raised coats to design spots—creates eye-catching contrast with matte areas. It resists scratches and fingerprints, frequently highlighting uv logos or graphics on book covers, labels, and custom retail boxes .

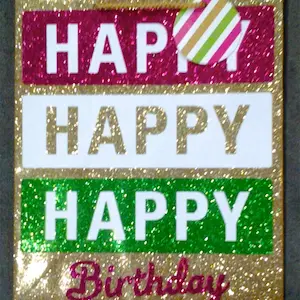

5. Glitter/Glitter Dust

Glitter dust adheres fine reflective particles to adhesive-coated surfaces, creating sparkle effects for festive or youth-oriented products . It requires precise application to minimize shedding, making it popular for holiday packaging, invitations, and promotional materials .

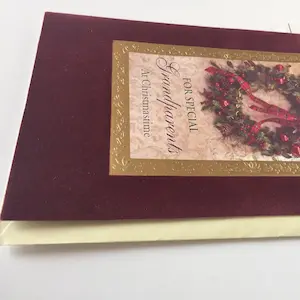

6. Flocking

Flocking bonds soft, velvety fibers to surfaces. This creates fabric-like textures using a special bonding process. It improves the feel of high-end gift boxes and cosmetic packaging. This creates a sense of luxury through warmth and depth.

7. Spot Embossing

Spot embossing selectively raises localized areas, such as uv logos or borders, without full-panel treatment. Less expensive. However, it still provides a nice touch for packaging and business items.

8. Die-Cut Windows/Window Patching

Die-cutting creates openings in packaging, revealing contents through transparent film (e.g., PET or acetate) patches . It enhances product visibility while minimizing material usage, making it perfect for food containers, electronics, and display packaging to capture consumer interest.

1. Foil Stamping

First, we create a custom metal stamp with your design. Heated to 120–150°C, it presses metallic or gold hot stamping foil onto surfaces using strong pressure. The heat activates the foil’s glue, transferring it onto surfaces like paper, leather, or plastic. This creates a shiny and durable finish.

2. Embossing Debossing

A male-female die set is mounted on a press, where the raised (embossing) or recessed (debossing) design is aligned with the substrate . High pressure (20–30 tons) is applied, permanently reshaping the material to create 3D texture without ink or foil .

3. Emboss + Foil (“Combo Stamping”)

Foil stamping starts by applying metallic foil to specific areas. The heated die then applies strong pressure. This embosses the foil design, combining shiny metal with a textured feel in one smooth step.

4. Spot UV

UV-curable resin is screen-printed onto specific design zones (e.g.,uv logo) using a stencil mask . The coating hardens quickly under UV lamps. This makes a shiny, raised surface that stands out from areas that are not coated.

5. Glitter Dust

We print the glue onto the design. And sprinkle small plastic glitter onto the wet glue. Excess glitter is vacuumed off, and the bonded layer is heat-cured for permanent adhesion and sparkle effect .

6. Flocking

Workers push tiny synthetic fibers straight onto glued surfaces. The fibers mix evenly into the glue layer. This creates a thick, soft nap after drying in tunnels.

7. Spot Embossing

A special stamp presses raised patterns onto material—only chosen spots, not the whole surface. Using 5–15 tons of pressure, it adds gentle texture safely.

8. Die-Cut Windows/Window Patching

Steel-rule dies cut window openings through the substrate using hydraulic presses . Transparent film (PET/acetate) is heat-sealed over the opening from behind, creating a sealed viewport without manual assembly .

1. Foil Stamping

Cost: Higher because of custom die creation (100–500) and gold hot stamping foil material costs (0.05–0.20 per unit). This option is best for mid-to-high-volume runs to spread out setup costs.

Advantage: Delivers metallic shine and luxury perception, elevating brand prestige for packaging or premium collateral .

Important: Avoid complex patterns with tiny details. This helps reduce gold foil waste and alignment problems. Set heat and pressure limits to prevent burning the substrate.

2. Embossing/Debossing

Cost: 0.10–0.50peritem.Metalstampscost80–300 upfront, but prices drop fast for 1,000+ units.

Advantage: Creates tactile 3D depth without inks—ideal for “blind” (unprinted) emboss logos or minimalist branding .

Use 250+ gram paper to avoid tears. Keep debossing under 0.5mm to maintain paper strength.

3. Combo Stamping (Emboss + Foil)

Cost: Premium (0.30–1.00/unit) because of dual-process setup and alignment precision.

Advantage: Combines metallic shine and texture for maximum sensory impact—e.g., luxury cosmetics or limited editions.

Note: Requires sequential die registration (foil first, then emboss); test on substrate samples to avoid adhesive cracking under pressure .

4. Spot UV

Cost: Low-to-moderate (0.05–0.20/unit); screen-printing setup fees apply, but UV-curable resin is cost-efficient .

Advantage: Adds scratch-resistant gloss contrast (e.g., matte + glossy areas), highlighting uv logos or graphics durably .

Use 1200+ dpi for crisp edges. Limit ink coverage to keep paper eco-friendly.

5. Glitter Dust

Cost: Low (0.03–0.15/unit); adhesive and polyester/PVC glitter are inexpensive, but manual application raises labor costs .

Advantage: Creates festive sparkle for seasonal gift packaging or invitations at minimal material cost .

Apply seal coat to stop shedding. Never use on food surfaces—microplastic health dangers.

6. Flocking

Cost: $0.15–0.40 each. Special equipment and synthetic fibers cost extra.

Advantage: Simulates velvet texture for high-touch appeal—e.g., custom gift boxes or premium cards .

Note: Requires adhesive curing (60–80°C); textured surfaces complicate stacking and increase shipping weight .

7. Spot Embossing

Cost: Low (0.08–0.25/unit); cheaper than full-panel embossing with targeted die areas .

Advantage: Focuses tactile impact on key elements (e.g., borders) while saving 30–50% vs. full embossing .

Note: Limit raised height to ≤0.3mm for uncoated papers; combine with spot UV to enhance durability .

8. Die-Cut Windows/Window Patching

Cost: Moderate (0.10–0.30/unit); steel-rule die fees (100–400) + transparent film (PET/acetate) material .

Advantage: Boosts product visibility and reduces packaging material by 15–25% vs. full-panel designs.

1. Matte vs. Glossy Foil Stamping

Matte gold foil hot stamping costs 15–25% more than glossy. It needs special handling to avoid burning.

Glossy gold logos uses common metal foils. Simple to apply, it cuts waste and setup time—so each unit costs less.

2. Matte vs. Glossy Spot UV

Matte UV adds ~20% cost for thicker, light-diffusing resins and slower curing to achieve uniform non-reflective texture .

Glossy UV is cheaper with standard high-gloss resins that cure faster under UV lamps, optimizing production throughput.

3. Embossing vs. Debossing Die Costs

Embossing stamps cost 10–15% more to make. They need precise matching parts for 3D effects.

Debossing dies cost less with simpler single-depth plates, though deep deboss (>0.5mm) risks substrate damage, increasing waste .

Q1: Which process has cheaper plate fees – embossing for custom wine boxes or spot UV for makeup boxes?

A: Digital spot UV: 0platefees∣∗∗Embossing∗∗:280-$520 die cost.

Q2: Are plate fees refundable if cancelling corrugated boxes order pre-production?

A: Only unused physical dies get 40-60% refund. Digital plates non-refundable.

Q3: Are sampling fees for apparel gift boxes high? Can they be credited?

A: 85−165/sample – fully credited against bulk orders of 3K+ units.

Q4: Can production reuse sample dies for wine glass gift boxes?

A: Yes! Same die used for sampling → mass production at zero extra tooling cost.

Q5: Will artwork changes to booklet boxes incur new plate fees?

A: Minor text changes: 0(digital)∣∗∗Layoutoverhaul∗∗:75-$220 new plate fee.

Deep Deboss/Emboss Techniques

Q6: Does deep debossing (>0.8mm) on wine gift boxes cost extra?

A: Yes: +0.12/unit∗∗formulti−leveldies+∗∗+85 setup for reinforced press.

Q7: Critical precautions for deep embossing on makeup boxes?

A: Must use ≤230gsm paper – thicker stocks fracture. Max depth: 1.2mm for safety.

Foil Stamping Economics

Q8: Can I choose custom foil colors for apparel gift boxes?

A: Yes! 200+ Pantone foils available – holographic/glow-in-dark cost extra.

Q9: Surcharge for metallic blue foil vs gold logos on corrugated boxes?

A: Special colors: +$35/pallet | Standard gold/silver: no extra charge.

Q10: Does multi-color gold logos on custom wine boxes multiply costs?

A: Each color: +120platefee+0.08/unit. Two-color logo = 2x cost.

Q11: Cheaper: full foil coverage, foil-laminated board, or gold printing for gift boxes?

A: Gold printing: 0.03/unit∣∗∗Foillamination∗∗:0.17/unit | Full foil hot stamping: $0.28/unit.

Q12: How to ensure consistent foil color across makeup box batches?

A: We track foil batches + control colors (ΔE<1.5) – limits color shifts under 3%.

Structural Engineering & Cost

Q1: Do booklet boxes with magnetic closures require thicker boards than folding boxes?

A: Yes! ≥2.5mm chipboard prevents warping under magnet pull (0.8-1.2kg force). Standard folding boxes use 1.8mm.

Q2: Why do deep embossing costs surge for rigid gift boxes vs corrugated?

A: Rigid boards need steel counter-dies (480+)vs foam for corrugated (160). Depth >1.5mm adds 35% pressure.

Material-Process Interactions

Q3: Can foil stamping adhere to uncoated kraft wine boxes?

A: Only with pre-coating (+$0.07/unit) – raw kraft absorbs foil unevenly. Gloss art paper recommended.

Q4: Why does debossing crack on thick makeup boxes?

A: 18pt+ boards fracture if deboss depth >0.6mm. Solution: laser scoring before pressing (+$0.12/unit).

Color Management

Q5: How to maintain identical gold foil across wine gift box batches?

A: Track foil batches + tight color checks. Without these, color shifts jump over 3.5.

Q6: Does bronze vs gold foil impact jewelry box perceived value?

A: Consumer testing shows 24K gold lifts premium perception 18% – worth +$0.09/unit cost.

Production Efficiency

Q7: Can corrugated boxes use same die for embossing and cutting?

A: No! Separate dies required – embossing plates crush flutes if combined. Adds $190 setup.

Q8: Why full coverage foil slows makeup box production 40%?

A: Foil requires cooling intervals to prevent overheating. Spot foil avoids this.

Hidden Defect Risks

Q9: Why do deboss logos peel on PU-coated gift boxes?

A: Silicone migration from coatings – specify foil-compatible aqueous coatings (e.g., ACTEGA 5075).

Q10: Do magnetic closures interfere with NFC tags in smart packaging?

A: Yes! Neodymium magnets disrupt RF signals. Keep >3cm distance or use ferrite magnets.

ALLEN LEE

Hi, I’m Allen Lee, the owner of Allenboxes.com, I’ve been in the packaging industry for over 20 years and running a factory in China that produce for 10+ years, and the purpose of this article is to share with you the knowledge related to packaging from a Chinese supplier’s perspective.

3 Steps to Save Shipping costs

Step 1: Use foldable boxes instead of two-piece rigid boxes.

Step 2: Customize to a smaller box. And Order early to use economy ocean freight instead of air.

Step 3: Select Door to door service include all taxes and freight.

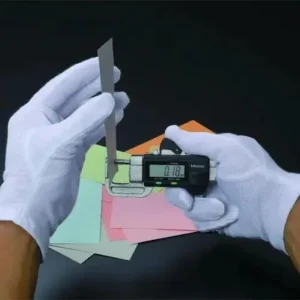

5 tips about Materials of Paper Boxes

1.Measure thickness of raw material

2.Cut a 10x10cm sheet

3.Measure paper weight

4.Measure paper thickness

5.Check standard weight-thickness tables

12 Common Box Inserts Introduction

1.Sponge (with velvet or paper)2.EVA Foam 3.Pearl cotton (EPE)

4.Paper Cardboard 5.Corrugated Paper 6.Plastic Blister

7.Tissue Paper 8.Raffia Filler9.Bubble Beads

10.Satin Fabric,11.Small Pouches 12.Mini Pillows

6 steps to customize paper boxes

1. Design Box style, Colors, Logos.

2. Meet the budget.

3. Revisions & Prototyping

4. Final Approval & Refinement

5. Small-Batch Testing

6. Mass Production

30 Common Sizes of Custom Boxes

4-step workflow to confirm Custom Box Sizes

Phase 1: Product & Dimension Fundamentals.

Phase 2: Box Type & Structural Design.

Phase 3: Budget-Driven Size Adjustments.

Phase 4: Prototyping & Refinement.

How to control color discrepancy of paper boxes

1.Same materials /ink batch

2.Same printing machines & crew

3.Same finishing (lamination/coating)

4.Identical inspection tools + standards

5. Smart color choices (e.g., black + embossed logo)