6 Top Popular Paper Bags

Paper bags are a type of packaging that has been around for centuries. They are made from paper, usually heavy-weight paper or cardstock, and are used for a variety of purposes. They are often used to package food, clothing, and other items for retail sale. They are also used to package items for shipping and storage.

Different kinds of Paper bag

- Carrier bags, euro tote shopping bags, with rope handles

- Paper Bags with paper handles

- Paper Bags with die-cutting handles

- Paper bags with ribbons glued

- Paper bags with handles and ribbons tied

- Paper Bags without handles

All details for the popular Paper Bags

| Packaging Style | Bags with knots, knotless, No handles, Glued ribbons, twisted paper handles,etc |

|---|---|

| Size | Customize based on the sizes of your products |

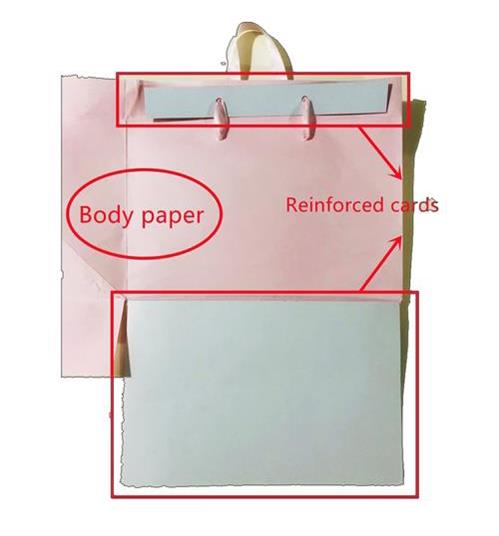

| Materials | 157 g art paper + 350 g reinforeced top and bottom cardboard |

| Printing | CMYK / Pantone Colors |

| Surface Finishing | Gloss / Matter Varnishing or Lamination |

| Special Finishing | Hot Foil, Emboss / Deboss , Spot UV, Glitter, Texture, Soft Touching Screen Printing, Die Cutting |

| Inserts | Foam, EVA, Paper, Blister, Flocked inserts, etc |

| Accessories | Handles, Ribbons, Magnets, 3M stickers, Envelopes, Tissue paper, etc |

| Packing | 1 pcs in each poly bag, 10 pcs in one outer carton |

| Shipping | Sea Freight,Air Freight,By Trains, etc |

2. Quantity

Usually, the MOQ is 3000 pcs for each size color logo and design. Because the basing printing costs are same about 85 USD between 100 pcs to 3000 pcs. The unit prices of 3000 pcs are much better than 100 pcs. More quantity, fewer unit prices.

Common paper, 157 gram & 250g coated two sides paper, 150 gram & 250g white kraft paper,150 gram & 250g black paper, Some other papers are below, like 170g,190g, 230g coated one-side paper, 120g, 180g white kraft paper, 120g,150g,180g,200g, and 250g brown kraft paper. Some art paper like textured paper, soft touching paper, dyeing paper, pearl paper, leather paper, wooden paper, clothes paper, gold card, silver card, glitter, etc.

Relief Printing, intaglio printing. Offset printing: CMYK printing, Pantone color printing, 5C 6C 7C(CMYK + Pantone)printing, on all kind of plain paper Silk printing. UV printing Ultra-Violet Ray printing on special paper (art paper), plastic, PVC, PE, etc. Lenticular printing

5. Surface finishing: glossy/ matte lamination,anti-scratch glossy/matte lamination, glossy/matte varnishing, soft touching lamination/varnishing, Texture lamination, holographic lamination, Anti-wear varnishing,

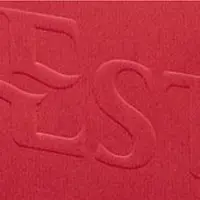

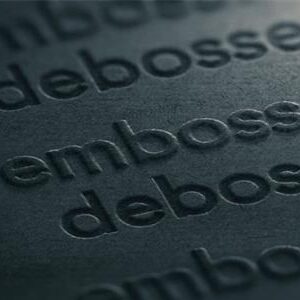

6. Special finishing . Glossy/Matte Hot foil(Hot stamping)(Gold, black, silver, pink, green, all colors are workable. See catalog and more pictures), Hot holographic foil, Emboss & deboss, Spot UV, 3D emboss, Hot foil & emboss, Glitter (Flitter)(single color or mix color), Flocking

7. Accessories1, Handles. Polyester rope handles, plastic rope handles, paper twisted handles, stain ribbons, silk ribbons, grosgrain ribbons, polyester ribbons, paper ribbons, cotton ribbons, custom color and logo on ribbons, triple twisted rope handles, gold & silver string handles, With plastic ends, metal ends, the paper ends,

8. Accessories2, Others like Gift tags, tissue paper, labels, stickers, thank you cards, J hook, Metal Eyelet, hairy balls, Pom pom balls, etc.

9. Packing. Usually 100 pcs bags pck in one big poly bag, then put in each K=K outer carton, 5 layers or 7 layers. And add the Plastic Anti-collision angle, paper Bumper strip to protect. Use the Desiccant to be moistureproof. Put two sheets of Anti-separation paper, etc.

10. Shipping. Sea shipping, express shipping, air shipping (air freight),etc

8 Steps to Customize Paper Bags

Customized paper bags are becoming increasingly popular for businesses looking to stand out from the competition. Not only do they look great, but they can also be used to promote your brand and show off your logo. Creating custom paper bags is a relatively simple process, but it does require some planning and attention to detail. Here are 30 steps to help you create the perfect custom paper bag for your business.

- Decide on the bag style, and size of your bag. This will depend on the items you plan to put in the bag.

- Choose the type of paper you want to use for your bag. You can use a variety of materials, including coated paper, Kraft paper, art paper, etc.

- Select a printing method for your bag. You can choose from offset printing, digital printing, screen printing, etc.

- Decide on the logo and design for your bag. This can be a simple or a more complex colorful design. If you are using a logo or design, create a digital file of it in a vector format. Choose the colors for your bag. You can use up to four colors.

- Select a surface finishing and special finishing on the logo. Like varnishing & lamination, Hot foil, emboss, texture, etc.

- Select a handle for your bag. You can choose from a variety of materials, including cotton, jute, and polypropylene.

- Check if more accessories are needed like tags, tissue paper, etc.

- Create the custom samples and check if any info needs to be improved. Arrange the Mass production after samples are approved and arrange the Shipping after all bags completed

3 details to Confirm what bags you need

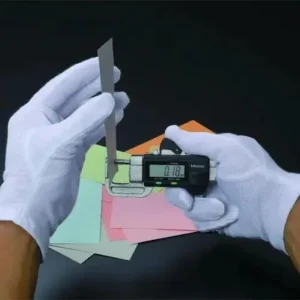

- Choosing the right paper, size, and rope handle for your paper bag is an important step in ensuring the quality of the bags. Here are some tips to help you pick the right thickness materials for your paper bag:

- Measure the size of the bag. This will help you determine the thickness of the paper and rope needed.

- Consider the weight of the items that will be placed in the bag. Heavier items require thicker paper and rope.

- Take into account the type of paper used. For example, Kraft paper is thicker than regular paper.

- By following these tips, you can ensure that you choose the right thickness for your paper bag. This will help you create a quality product that will last for years to come.

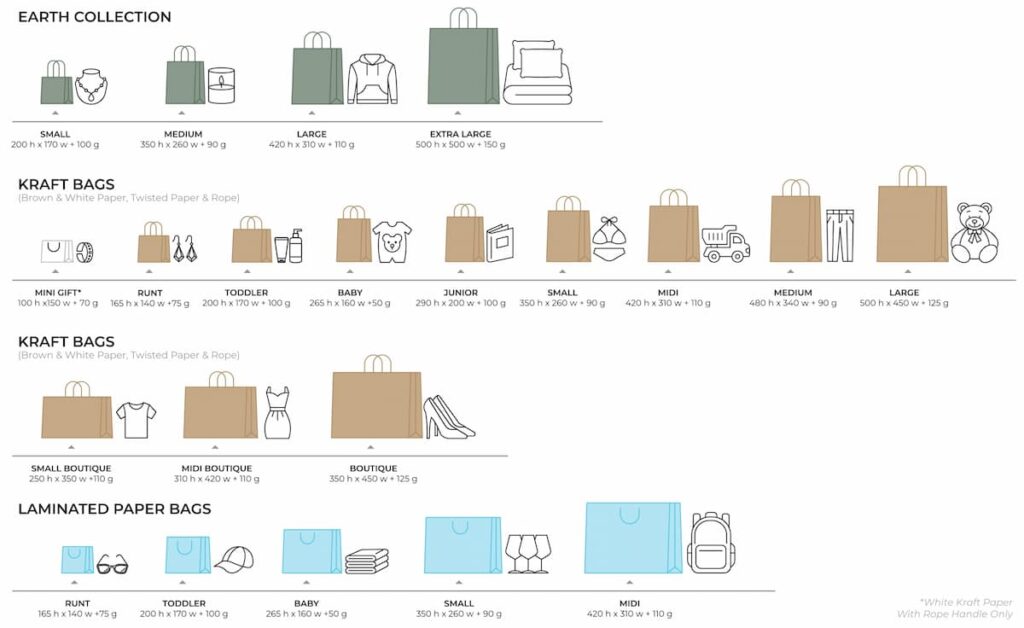

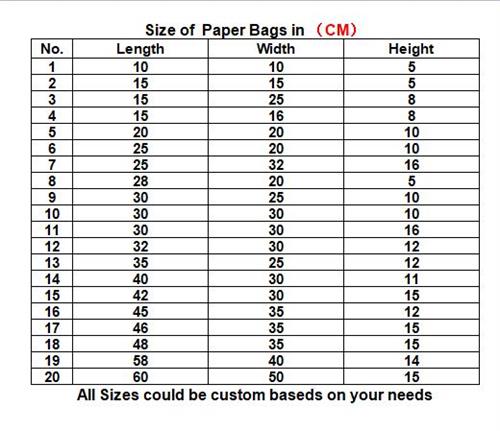

Here are some sizes of paper bags for reference. All size could be customized bsaed on your requirement.

10x10x5cm for jewelry packaging

15x15x6cm for smaller gift packaging

20x20x8 cm for shoulder paper bags

25x20x10 cm for paper gift bags

30x20x10 cm for shoe boxes packaging

32x28x15cm for gift boxes

35x25x12cm for coats packaging

40x35x15cm for sets of garments

42x30x15cm for Packaging the down jacket

60x50x20cm for Duvet

More special finishings mean higher costs. But It’s able to adjust the details to meet your budget, especially the finishing, accessories, etc. We will find the balance between luxurious and budget.

5 workable ways to get better prices of bags

1. More quantity, better unit prices.

Because the basing costs for printing, mold costs, finishing costs, and die cutting costs are similar between 10 pcs with 3000 pcs. About 80 USD for printing, 20 USD for mold costs, and 25 USD for die cutting. The unit printing cost for 10 pcs bags are 8 USD/pcs, 2usd/pcs for mold costs, and 2.5 USD/pcs for die-cutting costs. If for 3000 pcs, the unit printing cost is about 0.027 USD/pcs, about 0.007usd/pcs for mold costs and about 0.008 USD/pcs.

Such a big difference. This is also why we set MOQ to 3000 pcs which the prices are much better than 100 pcs.

2. Thinner paper but enough good quality.

Suitable or Less special finishing. If 1000 pcs bags with black logo only, the black hot stamping is advised. Because about 80 USD for hot stamping costs, and about 100usd for black ink printing costs.

Smaller Size. Smaller size, fewer materials costs, less handmade cost.

3. Slower shipping.

Slower shipping like Sea shipping or truck is with less cost.

4. Common handles & color paper.

Fewer customization costs if some common handles are suitable.

5. Stock bag.

No mold costs if you select some sizes we produced and have the molds in stock. Better prices if some bags are in stock and ready to ship are good for you also. We produced 5000 pcs at least to lower the production costs.

5 advantages of paper bags

1.Economic. Paper bags are inexpensive and can be bought in bulk. Less shipping costs which can be folded up for shipping and easy storage.

2.Easy to customize. Lower MOQ, easy to customize with logos, slogans, and designs. and company info.

3.Strong and good quality. Paper bags are strong and can hold a lot of weight. It’s good for carrying groceries, books, and other items.

4.Versatile. Paper bags are a great way to store and transport items. They are lightweight, inexpensive, and come in a variety of sizes, styles, and colors.

5.Recyclable. Paper bags are environmentally friendly. They are made from renewable resources and can be recycled. Paper bags can be reused multiple times. They are biodegradable and can be composted.

Disadvantages.

- Paper bags are not as strong as plastic bags and can tear easily. Paper bags are not as durable as plastic bags and can break down over time.

- Paper bags can be easily damaged by water and other liquids. Paper bags are not as resistant to chemicals and can be easily damaged.

- The costs of paper bags are higher than plastic bags.

Overall, paper bags have their advantages and disadvantages. They are lightweight, inexpensive, and environmentally friendly, but they are not as strong as plastic bags and can be easily damaged. It is important to consider both the pros and cons of paper bags before deciding which type of bag is best for your needs.

8 common production processings of custom paper bags

- Orders confirmed and deposit received

- Artwork is done & approved

- Plain or custom samples have been done & approved

- Mass production,paperwork like confirming how many sheets of paper are needed to source from the paper suppliers. How many designs are printed once to save? Improve the artwork and put some similar colors together.

- Source the materials like paper, cardboard, handles, and other accessories, create molds of die cutting and hot foil, Spot UV, etc. Printing as the paper arrived. Add the varnishing or lamination. Do the hot foil, emboss Spot UV or texture if there is. Die cut to the right & exact shape, also add the folding line of handmade to fold the bag Handmade, fold, and glue the sheet paper to one bag. Add top-reinforced top and bottom cards to make the bags stronger. Press them to glue them well.

- Keep you posted step by step during production.

- Inspection and Well Packaging.

- Pay the Balance before Shipping.

4 precautions to Check Quality of customized Paper bags

Paper bags are widely used in many industries, such as the packaging of food, medicine, and other products. Quality control of paper bags is important to ensure the safety and reliability of the products. Here are 10 tips and methods to check the quality of paper bags.

- Check the size of the bag. Make sure that it is not too small or too big for the product. Check the bag material. Make sure that it is suitable for the product and the environment. Check the bag design. Make sure that it is attractive and can draw customers’ attention.

- Check the bags printing quality. Make sure that the printing is clear and the colors are accurate. Check the bag surface. Make sure that there are no scratches or other damages. Check the bag for any uneven surfaces. Make sure that there are no uneven surfaces that may cause injury. Check the bag materials for any defects. Make sure that there are no tears, holes, or other defects. Check the bag edges. Make sure that they are properly cut and not damaged.

- Check the bag’s strength. Make sure that the box can bear the weight of the product. Check the box sealing quality. Make sure that the bag is well sealed to prevent leakage. Check the bag for any loose glue. Make sure that there is no loose glue that may cause injury. Check the bag corners. Make sure that the corners are properly cut and not damaged. Check the bag flaps. Make sure that the flaps are strong and can be opened and closed easily.

- Check the bag handles. Make sure that they are firmly attached and can bear the weight of the product. Check the bag for any glue residue. Make sure that there is no glue residue on the box. Check the bag for any sharp corners. Make sure that there are no sharp corners that may cause injury. Check the bag for any missing parts. Make sure that there are no missing parts that may cause injury.

By following these tips and methods, you can ensure the quality of paper bags and ensure the safety of the products. Quality control of paper bags is essential for any product packaging.

Get Wholesale Pricing Today

Save 10-15% on bulk bag orders with fast 10-20 days turnaround. Our team provides free design support to align packaging with your brand.

ALLEN LEE

Hi, I’m Allen Lee, the owner of Allenboxes.com, I’ve been in the packaging industry for over 20 years and running a factory in China that produce for 10+ years, and the purpose of this article is to share with you the knowledge related to packaging from a Chinese supplier’s perspective.

30 Common Sizes of Custom Boxes

4-step workflow to confirm Custom Box Sizes

Phase 1: Product & Dimension Fundamentals.

Phase 2: Box Type & Structural Design.

Phase 3: Budget-Driven Size Adjustments.

Phase 4: Prototyping & Refinement.

Top 8 Box Finishings

1. Foil Stamping2. Embossing/Debossing

3. Emboss + Foil (Combo Stamping)4. Spot UV

5. Glitter/Glitter Dust6. Flocking

7. Spot Embossing8. Die-Cut /Window Patching

12 Common Box Inserts Introduction

1.Sponge (with velvet or paper)2.EVA Foam 3.Pearl cotton (EPE)

4.Paper Cardboard 5.Corrugated Paper 6.Plastic Blister

7.Tissue Paper 8.Raffia Filler9.Bubble Beads

10.Satin Fabric,11.Small Pouches 12.Mini Pillows

5 tips about Materials of Paper Boxes

1.Measure thickness of raw material

2.Cut a 10x10cm sheet

3.Measure paper weight

4.Measure paper thickness

5.Check standard weight-thickness tables

How to control color discrepancy of paper boxes

1.Same materials /ink batch

2.Same printing machines & crew

3.Same finishing (lamination/coating)

4.Identical inspection tools + standards

5. Smart color choices (e.g., black + embossed logo)

6 steps to customize paper boxes

1. Design Box style, Colors, Logos.

2. Meet the budget.

3. Revisions & Prototyping

4. Final Approval & Refinement

5. Small-Batch Testing

6. Mass Production